What is the definition of high-speed PCB development?

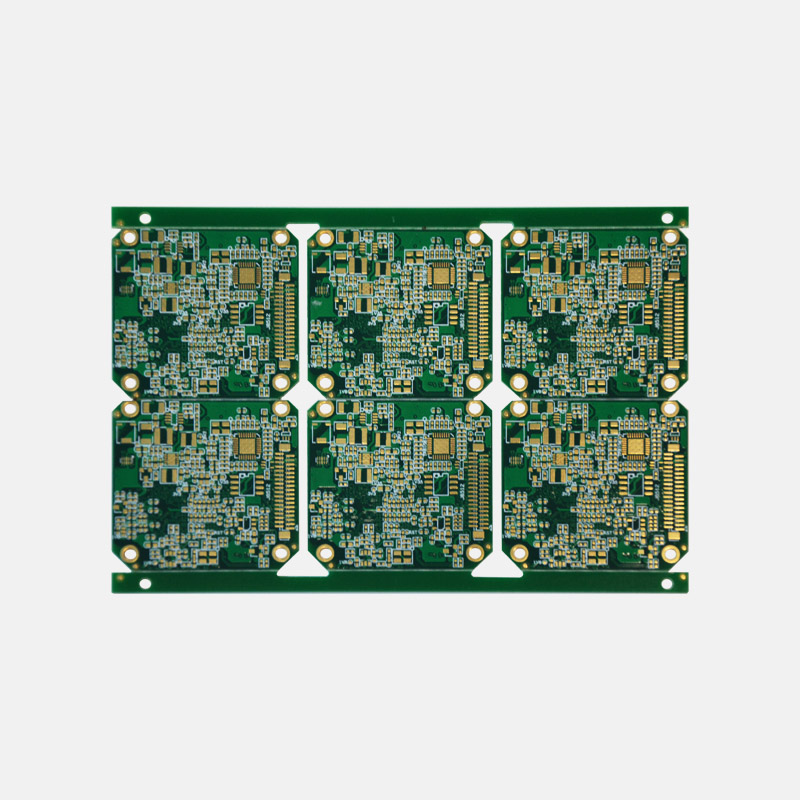

In the world of electronics, speed is of the essence. Whether it's for data transfer, signal processing, or overall system performance, the need for high-speed printed circuit boards (PCBs) has become paramount. High-speed PCB board development refers to the specialized design and manufacturing processes employed to create PCBs that can handle the rapid transmission of signals without signal degradation or loss. In this article, we'll explore the definition of high-speed PCB development and delve into its key aspects.

1. Understanding High-Speed PCBs

High-speed PCBs are designed to facilitate the rapid transmission of electrical signals, typically in applications where timing, signal integrity, and data integrity are critical. These PCBs are used in various industries, including telecommunications, data centers, aerospace, and high-performance computing. High-speed PCB development focuses on achieving several key objectives:

Signal Integrity: Ensuring that signals transmitted across the PCB board remain intact and free from distortion or noise.Minimized Crosstalk: Reducing electromagnetic interference between adjacent traces or components.Impedance Matching: Matching the impedance of transmission lines to optimize signal integrity.Reduced EMI/EMC: Minimizing electromagnetic interference (EMI) and electromagnetic compatibility (EMC) issues.Minimized Skew: Ensuring that signals arrive at their destination at the same time to prevent timing errors.

2. Design Considerations

High-speed pcb circuit board development begins with careful design considerations. Here are some critical aspects that designers need to address:

Layer Stackup: Determining the number of layers and their arrangement in the PCB stackup to control impedance and signal routing.Transmission Line Design: Calculating trace widths, spacing, and impedances to match the requirements of high-speed signals.Component Placement: Placing components strategically to minimize signal paths and reduce the risk of crosstalk.Grounding and Decoupling: Implementing proper grounding techniques and decoupling capacitors to control noise and ensure stable voltage levels.Signal Routing: Routing high-speed signals using controlled-impedance traces and minimizing vias to reduce signal reflections.

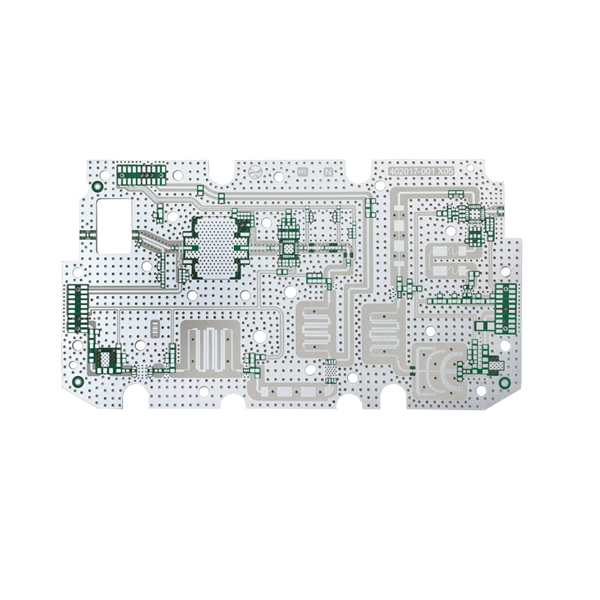

3. Material Selection

The choice of PCB material is critical in high-speed PCB manufacturing development. High-frequency signals require materials with specific electrical properties, such as low dielectric constant (Dk) and low dissipation factor (Df). Materials like FR-4 may be suitable for lower-speed applications, but for high-speed PCBs, designers often opt for advanced materials like PTFE (Teflon) or specialized laminates that offer better performance at high frequencies.

4. Manufacturing and Testing

Manufacturing high-speed PCBs requires specialized equipment and processes. Controlled impedance traces must be etched precisely, and manufacturing tolerances are tighter than for standard PCBs. Manufacturers also employ testing methods such as time-domain reflectometry (TDR) and eye diagram analysis to verify signal integrity and compliance with design specifications.

5. Evolution of High-Speed PCB Development

High-speed PCB development is an evolving field. As technology advances, the demand for higher data transfer rates and faster processing speeds continues to grow. This drives constant innovation in PCB design and manufacturing techniques. For example, the development of materials with even lower Dk and Df values and the use of advanced signal integrity simulation tools are pushing the boundaries of high-speed PCB capabilities.

In conclusion, high-speed PCB development is a specialized discipline within the world of electronics that focuses on creating PCBs capable of transmitting signals at rapid speeds while maintaining signal integrity. It involves careful design considerations, material selection, precise manufacturing processes, and ongoing innovation to keep pace with the demands of modern technology. High-speed PCBs are at the heart of many cutting-edge applications, enabling the seamless flow of data and ensuring the reliability of critical systems.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now