How to solve the problem of circuit board heating?

Addressing the challenge of circuit board heating is crucial for ensuring the optimal performance and longevity of electronic devices. In this article, we will explore effective strategies to prevent and resolve circuit board overheating concerns.

The Importance of Mitigating Circuit Board Overheating

Pcb circuit board overheating can lead to various issues, including reduced component lifespan, degraded performance, and even system failures. As electronic components become more advanced and power-dense, effective thermal management is becoming increasingly critical. By adopting suitable measures, we can enhance the reliability and efficiency of electronic systems while minimizing the risk of overheating.

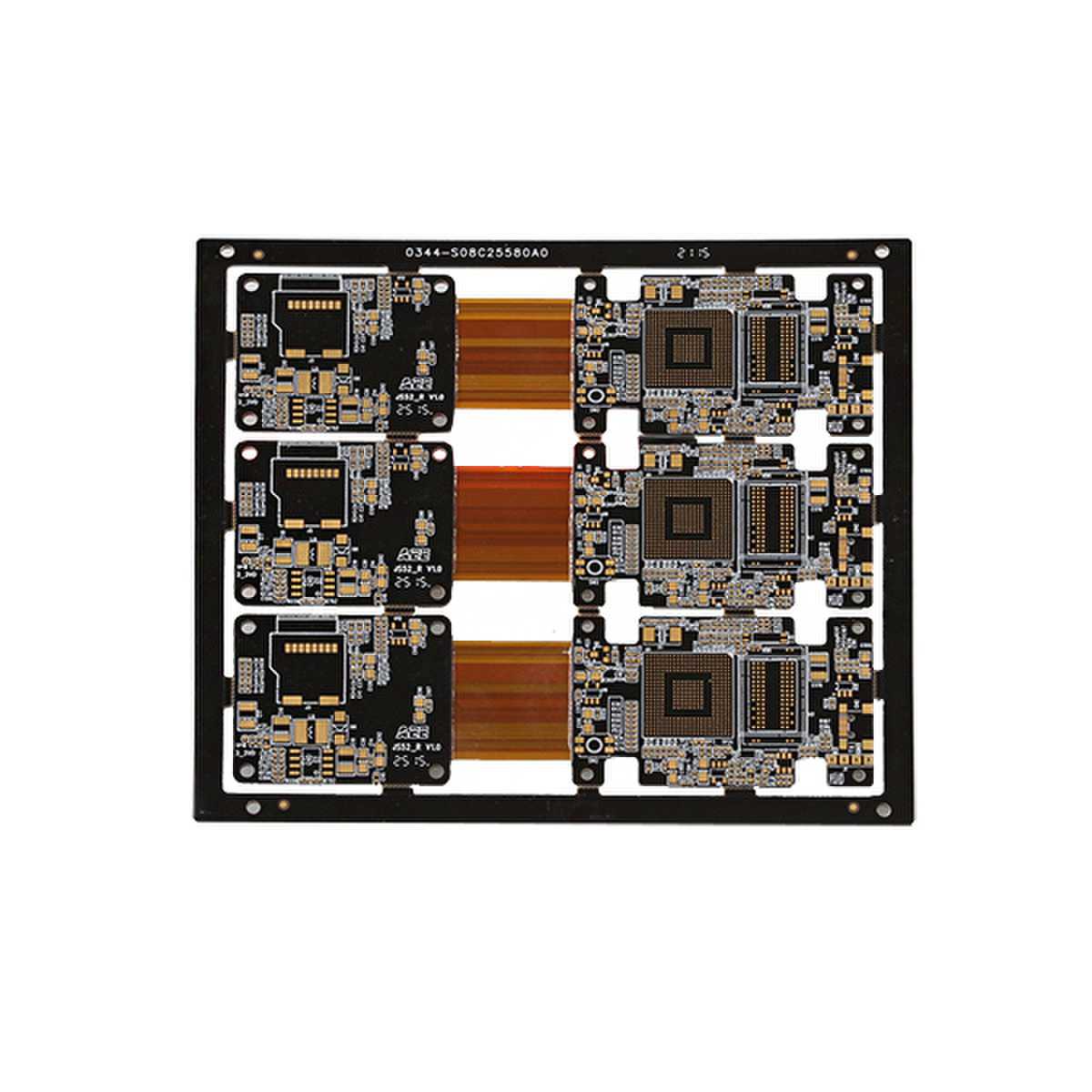

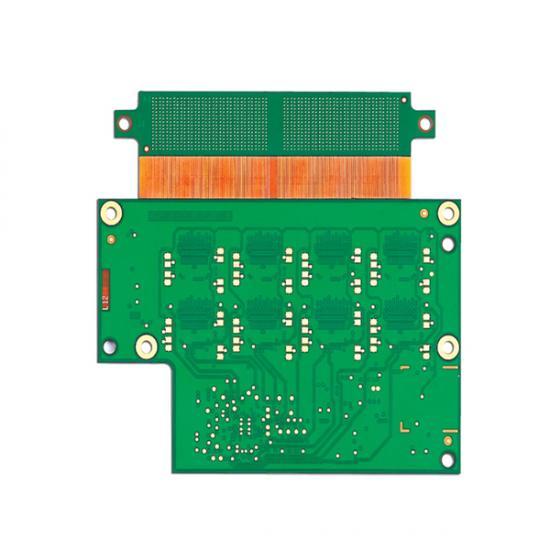

1. Proper Circuit Board Design

A well-designed circuit board is fundamental to mitigating heating problems. Here are some important considerations:

- Component Placement: Ensure sufficient space between heat-generating components to allow for proper airflow and heat dissipation.

- Heat Sinks: Utilize appropriate heat sinks or thermal pads to efficiently transfer heat away from high-power components.

- Thermal Vias: Implement thermal vias in the PCB design to improve heat conduction from the surface layer to inner copper layers.

- Layer Stacking: Consider using multiple layers in the PCB stackup to minimize thermal resistance and facilitate heat dissipation.

2. Effective Ventilation and Airflow

Proper airflow is crucial for dissipating heat from the circuit board. Implementing the following actions can help improve ventilation:

- Fans and Heat Sinks: Use fans and heat sinks to create airflow and facilitate heat transfer away from the board.

- Enclosure Design: Design the device's casing to allow for effective air circulation, ensuring cool air enters and hot air exits the system.

- Positioning: Place the device in a well-ventilated area, away from obstructions that may restrict airflow.

3. Thermal Management Materials

Using appropriate thermal management materials can significantly improve heat dissipation. Consider the following options:

- Thermal Interface Materials (TIMs): Apply high-quality TIMs between heat-generating components and heat sinks to enhance thermal conductivity.

- Thermal Pads and Adhesives: Use thermally conductive pads or adhesive tapes to establish efficient heat flow paths.

- Phase Change Materials (PCMs): Employ PCMs to absorb and release heat during temperature fluctuations, thereby regulating the system's thermal performance.

4. Monitoring and Control

Implementing effective monitoring and control mechanisms can help identify and manage potential overheating issues:

- Temperature Sensors: Integrate temperature sensors in critical areas to continuously monitor the temperature levels and trigger appropriate actions when necessary.

- Thermal Management Systems: Utilize advanced thermal management systems that can adjust fan speed or power output based on temperature readings.

- Software Controls: Implement software-based controls to manage power usage and reduce heat generation during heavy usage or high processing loads.

Conclusion

Effectively dealing with circuit board heating is vital to ensure the optimal functioning and longevity of electronic devices. By implementing appropriate circuit board design, enhancing ventilation and airflow, utilizing thermal management materials, and employing monitoring and control strategies, we can mitigate the risks associated with overheating. Giving due attention to thermal management will result in improved performance, increased reliability, and extended lifespan of electronic systems.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!