Why is immersion gold and gold plating on the PCB?

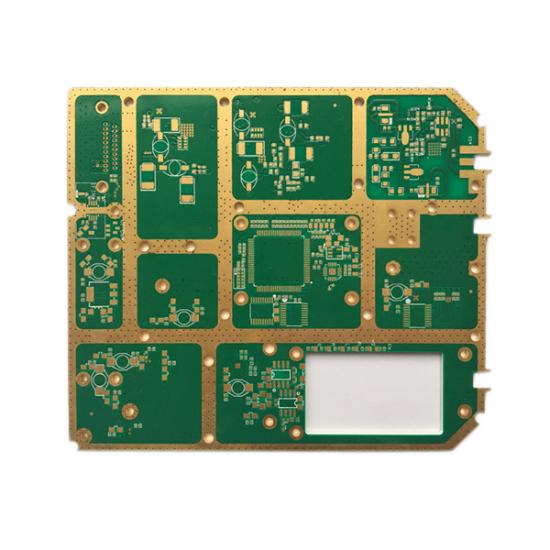

The PCB board is an indispensable part of electronic products. It carries electronic components and connects various circuits. In the manufacturing process of PCB boards, immersion gold and gold plating are two important process steps. This article will discuss why immersion gold and gold plating are required on PCB boards from the performance requirements of PCB boards, the role of immersion gold and gold plating, and the advantages and disadvantages of immersion gold and gold plating.

一.The performance requirements of the PCB board

As the core component of electronic products, PCB boards have very high performance requirements. First of all, the PCB board needs to have good electrical and thermal conductivity to ensure the normal operation of the circuit. Secondly, the PCB board needs to have good corrosion resistance and wear resistance to ensure the long-term stability of the circuit. In addition, the PCB board also needs to have good solderability and reliability to ensure the connection and work of electronic components.

二. The role of immersion gold and gold plating

1. The role of immersion gold

Immersion gold is an electrochemical deposition process. By depositing a layer of metal on the surface of the PCB, the conductivity and corrosion resistance of the PCB can be improved. Specifically, immersion gold can form a dense metal film on the surface of the PCB, which can effectively prevent oxidation and corrosion, and can also improve the solderability and reliability of the PCB.

2. The role of gold plating

Gold plating is an electrochemical gold plating process. By plating a layer of metal on the surface of the PCB, the conductivity and corrosion resistance of the PCB can be improved. Different from immersion gold, gold plating can form a more uniform and smooth metal film on the surface of the PCB, which can improve the conductivity and solderability of the PCB, and can also improve the appearance quality of the PCB.

三. Advantages and disadvantages of immersion gold and gold plating

1. Advantages and disadvantages of immersion gold

Advantages: immersion gold can form a dense metal film on the surface of the PCB, which can effectively prevent oxidation and corrosion, and can also improve the solderability and reliability of the PCB.

Disadvantages: The cost of immersion gold is high, and it will also increase the thickness of the PCB board, which will affect the performance of the PCB board.

2. Advantages and disadvantages of gold plating

Advantages: Gold plating can form a more uniform and smooth metal film on the surface of the PCB, which can improve the conductivity and solderability of the PCB, and can also improve the appearance quality of the PCB.

Disadvantages: The cost of gold plating is higher, and it will also increase the thickness of the PCB board, which will affect the performance of the PCB board.

To sum up, immersion gold and gold plating are very important process steps in the PCB board manufacturing process. They can improve the conductivity, corrosion resistance, solderability and reliability of PCB boards, and also improve the appearance quality of PCB boards. Although the cost of immersion gold and gold plating is high, they have a very important impact on the performance and quality of PCB boards, so they are indispensable in the PCB board manufacturing process.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now