Rigid-Flex PCBs: Enhancing Portability in Electronic Devices

In the rapidly evolving landscape of electronic devices, the demand for compactness and durability has never been greater. One innovation that stands out in meeting these demands is the Rigid-Flex Printed Circuit Board (PCB). This technology seamlessly integrates the benefits of both rigid and flexible PCBs, offering unparalleled advantages in terms of portability, reliability, and design flexibility.

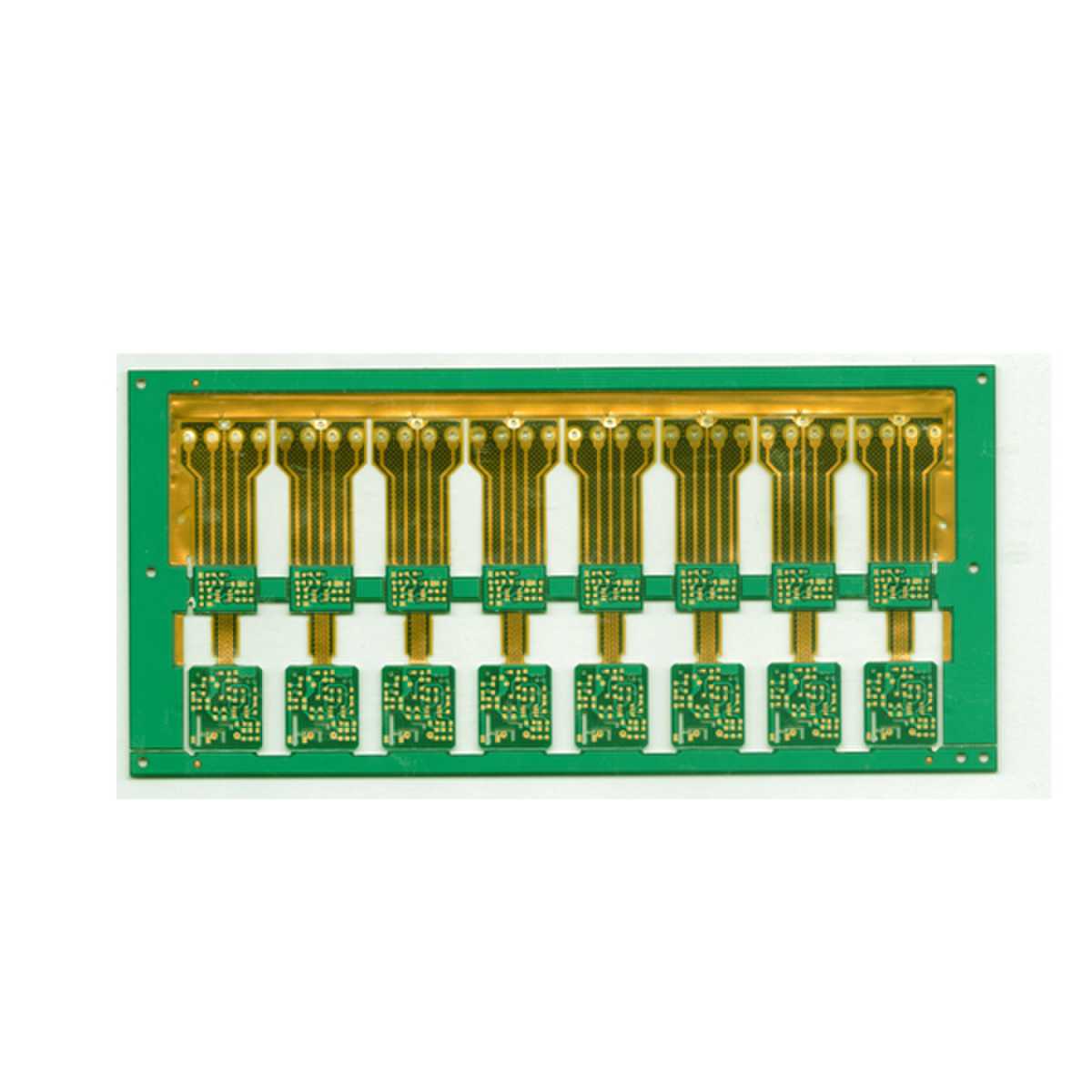

What are Rigid-Flex PCBs?

Rigid-Flex PCBs combine flexible circuit substrates with rigid boards, creating a single unit that allows for bending or folding without compromising structural integrity. This construction method eliminates the need for traditional wire harnesses and connectors, reducing overall weight and assembly complexity. By integrating rigid and flexible layers, Rigid-Flex PCBs can accommodate complex three-dimensional configurations, making them ideal for devices with space constraints.

Enhancing Portability

The primary advantage of Rigid-Flex PCBs lies in their ability to enhance portability in electronic devices. By reducing the number of interconnects and eliminating bulky connectors, these PCBs contribute to smaller, lighter, and more streamlined products. This is particularly beneficial in industries such as consumer electronics, medical devices, and aerospace, where compactness and weight reduction are critical.

Improving Reliability

In addition to portability, Rigid-Flex PCBs improve the reliability of electronic devices. The integrated design reduces the risk of connection failures and mechanical stress often associated with traditional PCB assemblies. This increased reliability translates to longer product lifespans and reduced maintenance costs, making Rigid-Flex PCBs a preferred choice for mission-critical applications.

Design Flexibility

Another significant advantage of Rigid-Flex PCB technology is its design flexibility. Engineers have greater freedom to design intricate layouts that optimize space and functionality. This flexibility enables the integration of multiple functions into a single board, simplifying assembly and enhancing overall system performance.

Applications Across Industries

Rigid-Flex PCBs find applications across various industries where compact, reliable, and high-performance electronics are required. In consumer electronics, such as smartphones and wearables, Rigid-Flex PCBs enable sleek designs and improved durability. In the medical field, these PCBs are used in devices ranging from pacemakers to diagnostic equipment, where reliability and miniaturization are critical. Aerospace applications benefit from Rigid-Flex PCBs' ability to withstand harsh environments and reduce weight, contributing to fuel efficiency and operational reliability.

Conclusion

In conclusion, Rigid-Flex PCB technology represents a significant advancement in the evolution of electronic devices. By combining the best features of rigid and flexible PCBs, these innovative solutions enhance portability, improve reliability, and offer unparalleled design flexibility. As demand grows for smaller, more reliable electronics across various industries, Rigid-Flex PCBs are poised to play a crucial role in shaping the future of technology.