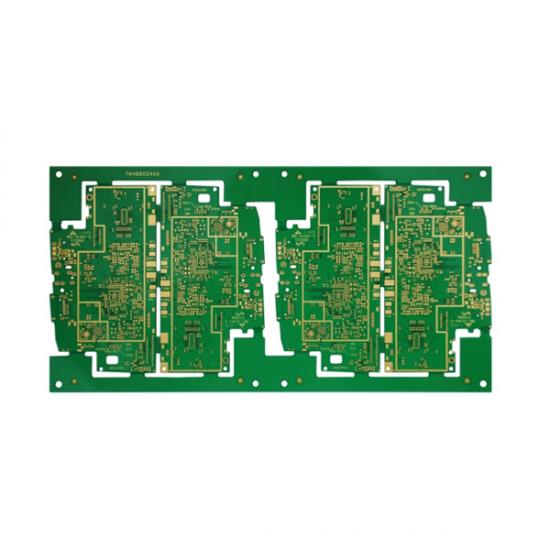

Elevate Your Electronics with High-Quality Multilayer 2+6+2 HDI PCB Boards

As technology continues to advance, the demand for more compact, efficient, and high-performance electronic devices grows. High-Density Interconnect (HDI) Printed Circuit Boards (PCBs) are at the forefront of this evolution, offering enhanced capabilities for modern electronic devices. In this blog post, we will explore the features, benefits, and applications of high-quality multilayer 2+6+2 HDI PCB boards, and why they are an essential component in today's tech industry.

What is a 2+6+2 HDI PCB?

HDI PCBs are characterized by their higher wiring density per unit area compared to traditional PCBs. The "2+6+2" configuration refers to a multilayer PCB with two outer layers, six inner layers, and two additional layers, typically used for advanced interconnect and microvia technology. This structure allows for more complex circuitry and higher performance.

Key Features of 2+6+2 HDI PCBs

1. High-Density Interconnects

The 2+6+2 HDI PCB configuration offers increased wiring density, which allows for more interconnections and components in a smaller area. This is crucial for compact and sophisticated electronic devices.

2. Microvias and Blind/Buried Vias

These PCBs utilize microvias, blind vias, and buried vias, enabling more efficient and reliable connections between layers. This technology improves signal integrity and reduces signal loss.

3. Multilayer Structure

With a total of ten layers, 2+6+2 HDI PCBs provide ample space for complex circuit designs. The multilayer structure supports advanced functionality and high-speed performance.

4. Improved Thermal Management

The multilayer design and high-quality materials used in 2+6+2 HDI PCBs enhance thermal management, dissipating heat more effectively and ensuring reliable operation of electronic components.

5. Enhanced Signal Integrity

The advanced design of HDI PCBs minimizes electromagnetic interference (EMI) and crosstalk, resulting in better signal integrity and overall device performance.

Benefits of High-Quality 2+6+2 HDI PCBs

1. Compact Design

HDI PCBs enable the design of smaller, lighter, and more compact electronic devices without compromising on performance. This is particularly important for mobile devices, wearables, and other portable technologies.

2. High Performance

The advanced interconnect technology and multilayer structure of 2+6+2 HDI PCBs support high-speed data transmission and improved performance, making them ideal for high-frequency applications.

3. Increased Reliability

The use of microvias and high-quality materials enhances the reliability and durability of HDI PCBs. These boards can withstand harsh operating conditions, ensuring long-term performance.

4. Design Flexibility

The multilayer configuration provides greater design flexibility, allowing engineers to create more complex and innovative circuit designs. This flexibility is essential for developing cutting-edge electronic products.

5. Cost-Effective Manufacturing

Despite their advanced capabilities, HDI PCBs can be manufactured cost-effectively. The use of automated manufacturing processes and high-quality materials reduces production costs while maintaining high standards of quality.

Applications of 2+6+2 HDI PCBs

1. Consumer Electronics

HDI PCBs are widely used in smartphones, tablets, laptops, and other consumer electronics, where compact design and high performance are critical.

2. Medical Devices

In the medical field, HDI PCBs are essential for developing advanced diagnostic and monitoring equipment, where precision and reliability are paramount.

3. Automotive Electronics

The automotive industry relies on HDI PCBs for developing advanced driver assistance systems (ADAS), infotainment systems, and other high-performance automotive electronics.

4. Aerospace and Defense

HDI PCBs are used in aerospace and defense applications, where high performance, reliability, and durability are required for mission-critical systems.

5. Industrial Automation

In industrial automation, HDI PCBs support the development of advanced control systems, robotics, and other high-performance industrial equipment.

Conclusion

High-quality multilayer 2+6+2 HDI PCB boards are revolutionizing the electronics industry, offering unmatched performance, reliability, and design flexibility. Their compact design, advanced interconnect technology, and cost-effective manufacturing make them an essential component in modern electronic devices. Whether in consumer electronics, medical devices, automotive systems, aerospace, or industrial automation, 2+6+2 HDI PCBs are paving the way for the next generation of technological advancements. Investing in high-quality HDI PCBs ensures that your electronic products meet the highest standards of performance and reliability, positioning your brand at the forefront of innovation.