Understanding 2-Layer Rigid-Flex PCBs: Benefits and Applications

In the rapidly evolving world of electronics, the demand for compact, reliable, and versatile circuit boards is higher than ever. Two-layer rigid-flex PCBs (Printed Circuit Boards) have emerged as a popular solution, offering the benefits of both rigid and flexible circuits. This article explores the benefits and applications of 2-layer rigid-flex PCBs, providing insights into why they are increasingly favored in modern electronic designs.

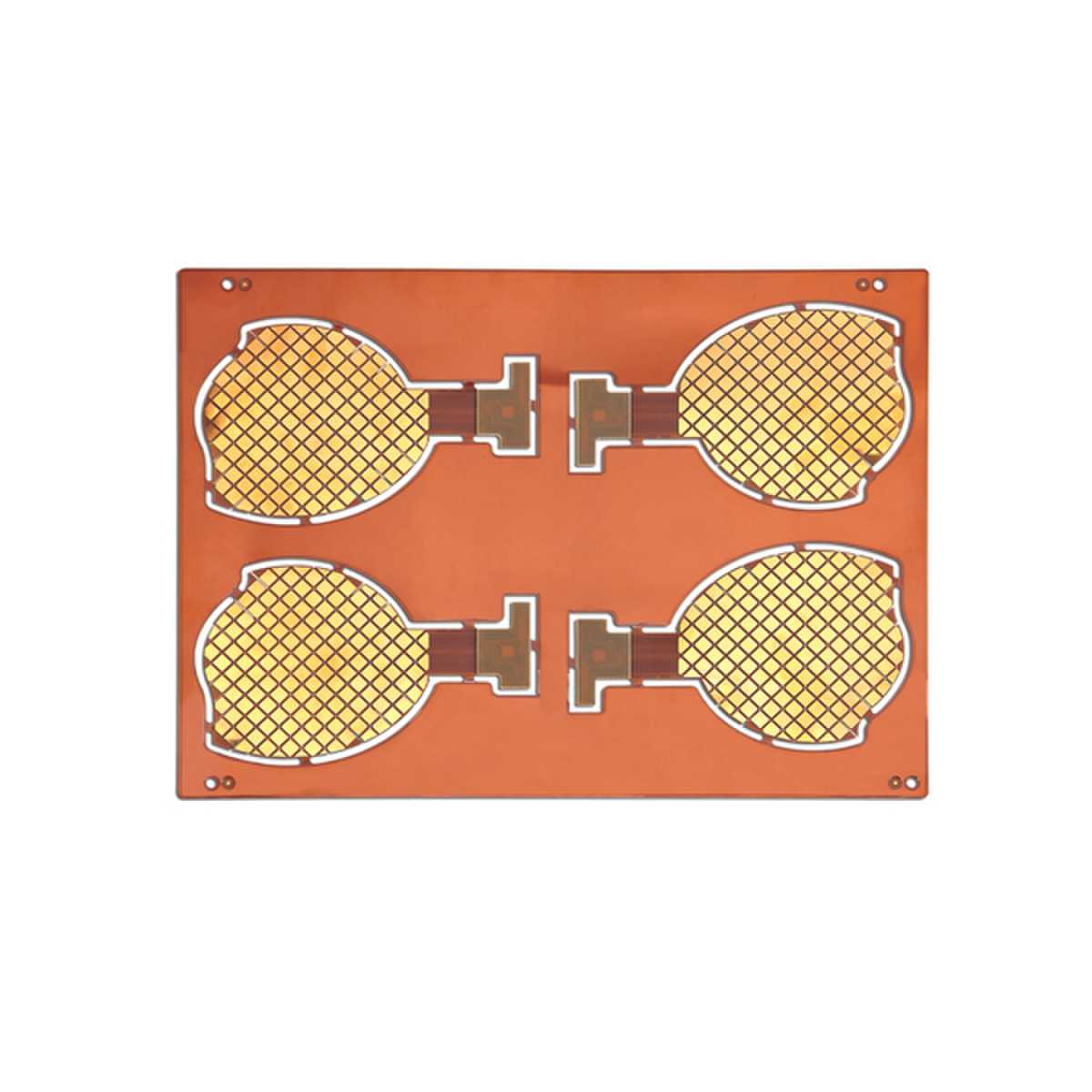

What Are 2-Layer Rigid-Flex PCBs?

Two-layer rigid-flex PCBs are composed of both rigid and flexible substrates integrated into a single board. This design combines the durability and structural integrity of rigid PCBs with the flexibility and lightweight characteristics of flexible circuits. The 2-layer configuration means that there are two conductive layers, which can be used for more complex circuits compared to single-layer PCBs.

Benefits of 2-Layer Rigid-Flex PCBs

1. Space Efficiency:

The combination of rigid and flexible sections allows for more compact designs, enabling components to be placed closer together. This is particularly beneficial in applications where space is at a premium.

2. Reliability and Durability:

Rigid-flex PCBs are known for their mechanical stability and durability. The rigid parts provide structural support, while the flexible sections can withstand bending and movement, reducing the risk of failure in dynamic applications.

3. Reduced Weight:

By integrating flexible circuits with rigid boards, the overall weight of the PCB assembly is reduced. This is advantageous in applications such as aerospace and portable electronics, where weight savings are crucial.

4. Simplified Assembly:

The integration of rigid and flexible sections into a single PCB reduces the need for connectors and cables, simplifying the assembly process and improving signal integrity by minimizing potential points of failure.

5. Enhanced Design Flexibility:

Designers can take advantage of the flexible sections to create complex three-dimensional shapes, allowing for innovative and space-efficient electronic products.

Applications of 2-Layer Rigid-Flex PCBs

1. Consumer Electronics:

In smartphones, tablets, and wearable devices, 2-layer rigid-flex PCBs are used to connect different components while maintaining a slim profile. The flexibility allows for bending around tight corners and fitting into compact spaces.

2. Medical Devices:

Medical equipment often requires reliable and compact circuitry. Rigid-flex PCBs are used in devices such as pacemakers, hearing aids, and diagnostic equipment, where flexibility and durability are essential.

3. Aerospace and Defense:

The aerospace and defense industries benefit from the lightweight and reliable nature of rigid-flex PCBs. They are used in avionics, satellite systems, and military communication devices, where both performance and weight are critical factors.

4. Automotive Electronics:

In modern vehicles, rigid-flex PCBs are employed in advanced driver-assistance systems (ADAS), infotainment systems, and engine control units. Their ability to withstand harsh environments and vibrations makes them suitable for automotive applications.

5. Industrial Equipment:

Industrial automation and control systems use rigid-flex PCBs to manage complex circuits in a compact form. They are found in robotics, manufacturing equipment, and control panels, where reliable performance is crucial.

Conclusion

Two-layer rigid-flex PCBs offer a versatile and efficient solution for modern electronic designs. Their unique combination of rigidity and flexibility provides numerous benefits, including space efficiency, reliability, reduced weight, simplified assembly, and enhanced design flexibility. These advantages make them ideal for a wide range of applications, from consumer electronics to aerospace and medical devices. As technology continues to advance, the demand for rigid-flex PCBs is likely to grow, driving further innovations in electronic design and manufacturing.