Can Rigid PCBs Be Customized for Specific Applications?

In the world of electronics manufacturing, the evolution of technology has necessitated the development of printed circuit boards (PCBs) that are not only reliable and efficient but also customizable to meet specific application requirements. Rigid PCBs, known for their structural integrity and stability, have not lagged behind in this aspect. This article delves into the realm of customization for rigid printed circuit board and explores the ways in which these boards can be tailored to suit the unique demands of various applications.

Understanding Rigid PCBs

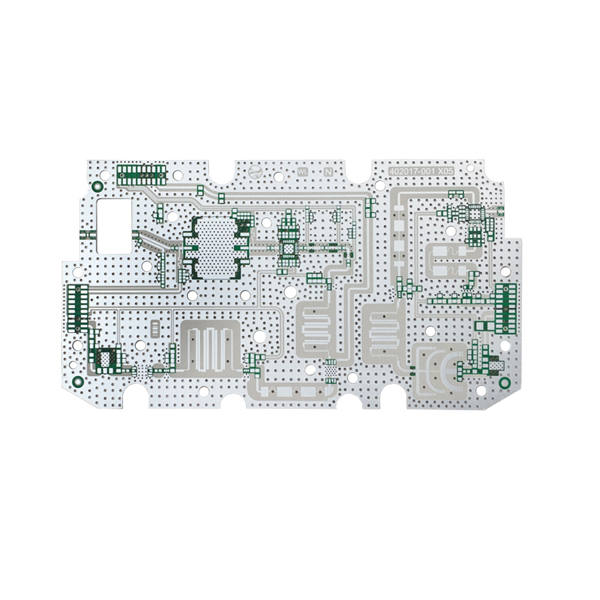

Rigid PCBs, also known as rigid-flexible pcb, are the foundation of countless electronic devices. They are composed of a solid substrate material, usually a non-flexible material like fiberglass, which provides structural support and stability to the components mounted on the board. This rigidity is a key characteristic that sets them apart from flexible PCBs. Rigid PCBs are widely used in applications ranging from consumer electronics to industrial equipment due to their durability and reliability.

Customization Possibilities

Customizing rigid PCBs involves tailoring their design, layout, and features to match the specific requirements of an application. This customization can encompass various aspects, including:

1. Board Size and Shape:custom circuit board can be manufactured in a variety of shapes and sizes, allowing designers to create boards that fit perfectly within the available space of the target device. Whether it's a compact wearable device or a large industrial control panel, the board can be designed to maximize efficiency and functionality.

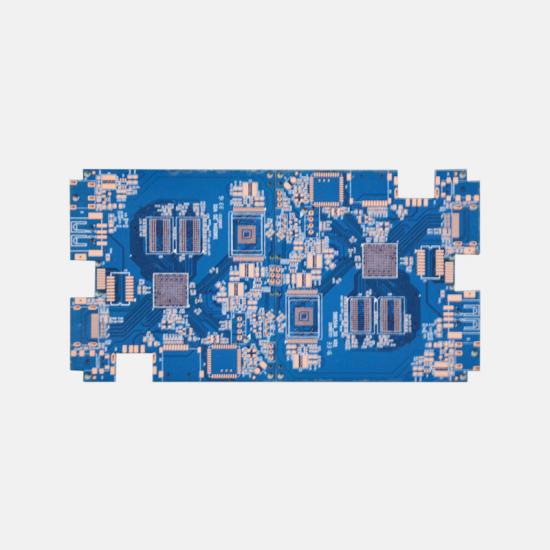

2. Layer Configuration:Rigid PCBs can be designed with multiple layers, each accommodating different components and connections. The layer configuration can be customized to accommodate the required circuit complexity, from simple single-layer designs to intricate multilayer boards.

3. Component Placement:The precise placement of components on a PCB can significantly impact performance and efficiency. Designers can customize component placement to optimize signal integrity, reduce interference, and ensure efficient heat dissipation.

4. Materials:Rigid PCBs can be customized with specific materials that are suited to the application's environmental conditions, such as temperature, humidity, and chemical exposure. This ensures the longevity and reliability of the board in challenging operational environments.

5. Trace Width and Spacing:Customization also extends to the width and spacing of traces on the board. Designers can adjust these parameters to accommodate higher currents, reduce signal interference, and enhance overall circuit performance.

6. Connectivity:The type and number of connectors and interfaces on a rigid PCB can be tailored to the application's connectivity needs. This includes USB ports, HDMI connectors, Ethernet jacks, and more.

Benefits of Customization

The ability to customize rigid PCBs for specific applications offers several advantages:

1. Optimized Performance:Tailoring the board's design to the application's requirements enhances overall performance and efficiency. This can result in improved signal integrity, reduced power consumption, and better thermal management.

2. Space Efficiency: Customized designs ensure that the PCB fits perfectly within the available space, allowing for more compact and streamlined device designs.

3. Reliability:Using materials and components suited to the application's environment ensures the longevity and reliability of the PCB, reducing maintenance and replacement costs.

4. Reduced Costs:Customization eliminates unnecessary features and components, resulting in cost savings during production.

5. Faster Time-to-Market:By eliminating design iterations and adjustments, customized rigid PCBs can accelerate the product development process.

Conclusion:

The world of electronics is diverse and dynamic, demanding solutions that are as unique as the applications they serve. Rigid PCBs, with their robust structure and design flexibility, provide an ideal platform for customization. The ability to tailor these boards to specific application requirements allows for optimized performance, enhanced reliability, and efficient use of resources. As technology continues to advance, the customization of rigid PCBs will remain a vital tool for designers and engineers seeking to create innovative and effective electronic devices.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!