Why choose 4-layer PCB board?

Benefits of Choosing a 4-layer PCB board for Electronic Devices

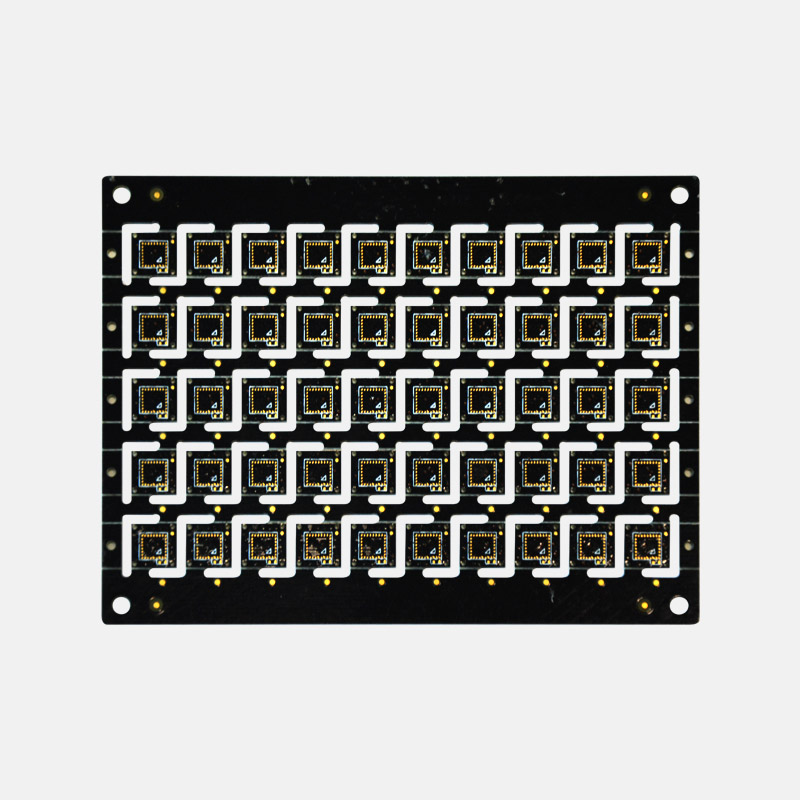

Printed Circuit Boards (PCBs) are crucial components in the world of electronics. They provide a platform for interconnecting various electronic components, ensuring the smooth functioning of devices. When it comes to choosing the right PCB for your electronic device, the number of layers plays a significant role. In this article, we will explore the reasons why opting for a 4-layer PCB board can be advantageous.

1. Enhanced Routing Capabilities

A 4-layer PCB board offers improved routing capabilities compared to boards with fewer layers. The additional layers provide more space for routing traces and signal paths. This means that designers have greater freedom to design complex circuits and achieve high-density interconnections. The increased routing capabilities of a 4-layer PCB board are especially beneficial for high-speed and multilayered electronic devices.

2. Greater Signal Integrit

Signal integrity is crucial in electronic devices as it ensures the accurate transmission of data and signals without distortion. With a 4-layer PCB board, you have dedicated inner layers that can be effectively utilized for power planes and ground planes. This separation reduces the chances of electron theft or noise coupling, resulting in improved signal integrity and reduced electromagnetic interference (EMI).

3. Noise Reduction

Noise interference is a common issue in electronic devices, and it can have a significant impact on their performance. The additional layers in a 4-layer PCB board act as noise shields, effectively reducing the impact of both external and internal noise sources. The separation of power and ground planes, along with controlled impedance, enables better noise control, resulting in enhanced device performance.

4. Thermal Management

Electronic devices generate heat during operation, and effective thermal management is necessary to ensure their longevity and reliability. With a 4-layer PCB board, you have more space to implement heat dissipation techniques such as thermal vias or heat sinks. The additional layers provide better thermal conductivity, allowing for efficient heat dissipation, thus preventing overheating issues that could potentially damage the components.

5. Space Optimization

As electronic devices are becoming smaller and more compact, space optimization is a critical factor in PCB design. By using a 4-layer PCB board, designers can achieve high component density while minimizing the overall size of the device. The extra layers allow for more efficient component placement and trace routing, thereby reducing the size of the PCB without compromising its functionality.

6. Design Flexibility and Future Expansion

One of the significant advantages of a 4-layer PCB board is the design flexibility it offers. The additional layers provide ample space for accommodating circuitry changes or adding new components without the need to redesign the entire board. This flexibility is particularly useful in situations where the device undergoes upgrades or when new functionalities need to be added in the future.

In conclusion, a 4-layer PCB board offers numerous advantages when it comes to electronic device design. The enhanced routing capabilities, improved signal integrity, noise reduction, thermal management, space optimization, and design flexibility make it a preferred choice for various industries. So, if you are looking for a high-performance and reliable PCB solution, choosing a 4-layer PCB board is a wise decision.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!