Unlocking Efficiency: The Benefits of PCBA Custom Solutions in Electronics Manufacturing

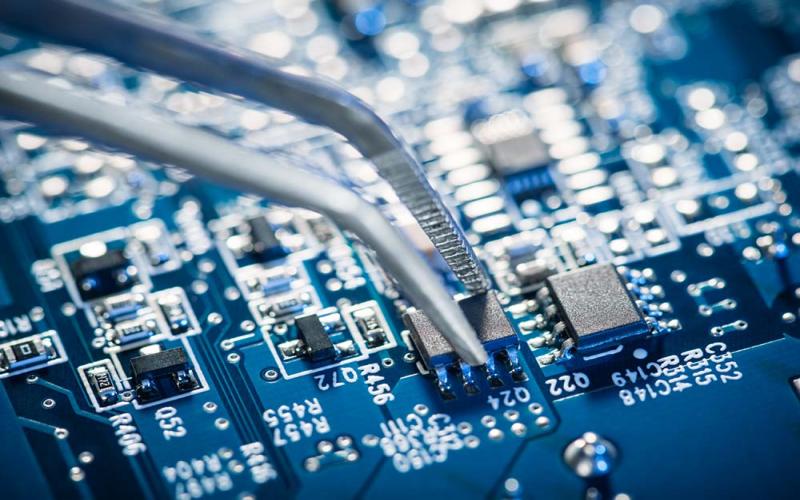

In the ever-evolving landscape of electronics manufacturing, efficiency and innovation are paramount. One of the key advancements driving these factors is the use of custom printed circuit board assemblies (PCBA). Custom PCBA solutions have revolutionized the electronics industry, offering a plethora of benefits that enhance both the manufacturing process and the final products. This article explores the significant advantages of PCBA custom solutions and their impact on electronics manufacturing.

Tailored Design and Precision

Custom PCBA solutions allow manufacturers to design and produce circuit boards tailored to the specific needs of their products. This level of customization ensures that each PCBA fits perfectly within the device, optimizing space and performance. Precision in design translates to higher efficiency in manufacturing and operation, reducing the likelihood of errors and malfunctions.

Enhanced Performance and Reliability

By utilizing custom PCBA, manufacturers can select the best components and materials for their specific applications. This tailored approach ensures that the final product operates at peak performance and reliability. Custom PCBA solutions also allow for better thermal management and electrical performance, which are critical factors in the longevity and efficiency of electronic devices.

Cost-Effectiveness

While custom PCBA solutions may have a higher upfront cost compared to standard off-the-shelf options, they often result in significant cost savings in the long run. Custom assemblies can reduce the need for additional components and rework, leading to lower manufacturing costs. Additionally, optimized PCBA designs can improve energy efficiency, resulting in cost savings during the device's operational life.

Speed and Flexibility in Production

Custom PCBA solutions streamline the production process by eliminating the need for modifications and adjustments during assembly. This efficiency speeds up production timelines and allows manufacturers to respond quickly to market demands. The flexibility of custom PCBAs also enables rapid prototyping and iteration, which is essential for staying competitive in the fast-paced electronics industry.

Improved Product Integration

Custom PCBA solutions facilitate seamless integration of various electronic components within a device. This integration is crucial for the development of compact and multifunctional products. By optimizing the layout and connections, custom PCBAs can enhance the overall functionality and user experience of electronic devices.

Scalability and Future-Proofing

As technology advances, the ability to scale and adapt to new requirements is essential. Custom PCBA solutions provide the scalability needed to accommodate future upgrades and changes. This future-proofing capability ensures that electronic devices remain relevant and efficient as new technologies emerge.

Applications in Various Industries

Custom PCBA solutions are utilized across a wide range of industries, each benefiting from the tailored approach to circuit board design and assembly. Some notable applications include:

Consumer Electronics: Smartphones, tablets, and wearable devices require highly customized PCBAs to fit within their compact and intricate designs.

Automotive Industry: Modern vehicles rely on custom PCBAs for advanced features such as infotainment systems, navigation, and safety mechanisms.

Medical Devices: Precision and reliability are paramount in medical devices, making custom PCBAs essential for diagnostic equipment, patient monitors, and surgical instruments.

Industrial Equipment: Custom PCBAs in industrial machinery ensure robust performance and durability, critical for demanding operational environments.

Aerospace and Defense: High-performance and reliability are crucial in aerospace and defense applications, where custom PCBAs support navigation, communication, and control systems.

Conclusion

The benefits of custom PCBA solutions in electronics manufacturing are undeniable. From tailored design and enhanced performance to cost-effectiveness and improved product integration, custom PCBAs play a vital role in driving efficiency and innovation. As the electronics industry continues to evolve, the adoption of custom PCBA solutions will remain a cornerstone of competitive manufacturing, enabling the production of advanced, reliable, and high-performing electronic devices. For manufacturers looking to stay ahead in the market, embracing custom PCBA solutions is not just an option but a necessity.