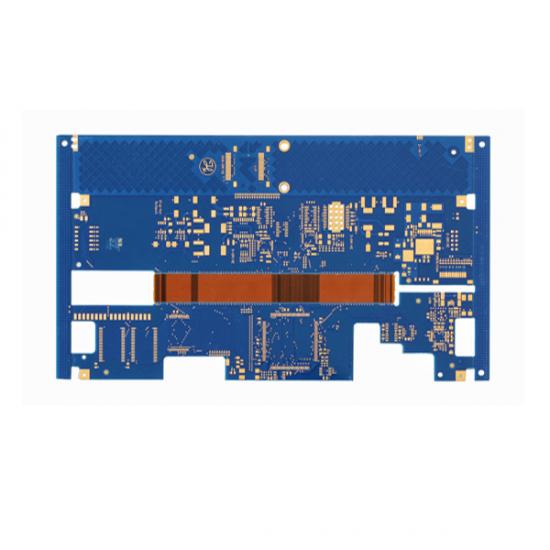

6 Layer Rigid-Flex Circuit Boards for Medical Devices: Enhancing Performance and Reliability

The medical device industry demands high-performance, reliable, and compact solutions to support the complex needs of modern healthcare. One of the key components meeting these requirements is the 6 layer rigid-flex circuit board. These advanced PCBs combine the benefits of both rigid and flexible circuits, offering unparalleled performance and durability. In this blog post, we'll explore how 6 layer rigid-flex circuit boards enhance medical devices and why they are essential for the future of medical electronics.

What Are 6 Layer Rigid-Flex Circuit Boards?

Rigid-flex circuit boards are a hybrid of rigid and flexible PCBs, allowing for a combination of rigid and flexible substrates in a single board. The "6 layer" designation indicates that the PCB consists of six layers of conductive material, typically copper, which are interconnected to form a single, cohesive unit. This design provides both the stability of rigid boards and the adaptability of flexible circuits.

Benefits of 6 Layer Rigid-Flex Circuit Boards in Medical Devices

1. Enhanced Reliability

Medical devices require high reliability due to the critical nature of their applications. 6 layer rigid-flex PCBs offer robust performance, reducing the risk of failure. The combination of rigid and flexible layers ensures that the circuit can withstand mechanical stresses, bending, and flexing without compromising functionality.

2. Compact and Lightweight Design

Medical devices often need to be compact and lightweight, especially wearable and portable ones. Rigid-flex PCBs allow for a more compact design by eliminating the need for connectors and cables between rigid boards. This integration reduces the overall weight and size of the device, making it more comfortable and convenient for patients and healthcare providers.

3. Improved Signal Integrity

With multiple layers, rigid-flex PCBs can handle complex circuits and high-speed signals more efficiently. This results in better signal integrity and reduced interference, which is crucial for the accurate and reliable operation of medical devices. The layered design also allows for better thermal management, dissipating heat more effectively.

4. Greater Durability

The combination of rigid and flexible layers provides enhanced durability, making these PCBs ideal for medical devices that are subject to frequent movement and handling. The flexible layers can absorb shocks and vibrations, protecting the rigid sections and ensuring the longevity of the device.

Applications in Medical Devices

6 layer rigid-flex circuit boards are used in various medical devices, including:

Wearable Health Monitors: Devices like ECG monitors and fitness trackers benefit from the lightweight and flexible nature of these PCBs.

Diagnostic Equipment: High-precision diagnostic tools require reliable and interference-free operation, which rigid-flex PCBs provide.

Surgical Instruments: The compact design allows for the integration of advanced electronics in surgical tools, enhancing their functionality and precision.

Imaging Systems: Medical imaging devices, such as MRI and ultrasound machines, utilize these PCBs for their superior signal integrity and durability.

Conclusion

6 layer rigid-flex circuit boards are revolutionizing the medical device industry by providing enhanced performance, reliability, and compact design. Their ability to withstand mechanical stresses, maintain signal integrity, and reduce the overall size and weight of devices makes them an indispensable component in modern medical electronics. As the healthcare industry continues to advance, the adoption of rigid-flex PCBs will undoubtedly play a crucial role in developing innovative and effective medical devices.

By understanding the benefits and applications of 6 layer rigid-flex circuit boards, manufacturers and designers can make informed decisions to create cutting-edge medical devices that meet the high standards of performance and reliability required in healthcare.