Implementing Flexible PCBs for Lightweight Solutions

Revolutionizing the Electronics Industry

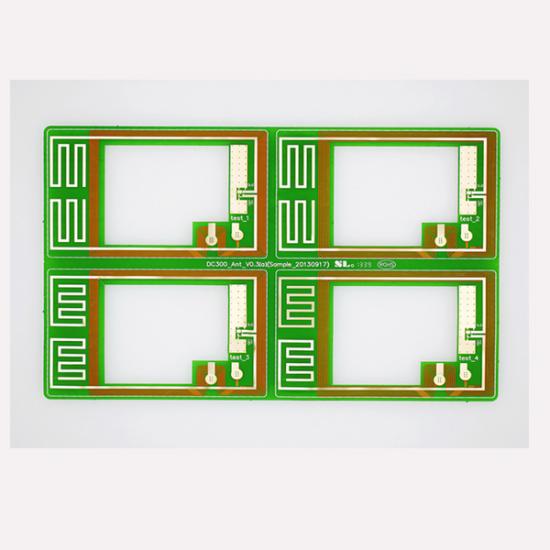

Flexible PCBs, also known as flex circuits, have transformed the way we design and manufacture electronic devices. Their ability to bend, twist, and conform to irregular shapes makes them a game-changer in the pursuit of lightweight solutions. In this article, we will explore the various aspects of implementing flexible PCBs to achieve innovative and lightweight electronic designs.

The Advantages of Flex PCBs

Flex PCBs offer numerous advantages over traditional rigid PCBs. Firstly, their lightweight nature contributes significantly to reducing the overall weight of electronic devices, making them ideal for portable applications without compromising functionality. Additionally, flexible PCBs can be customized to fit into non-traditional form factors, maximizing available space and enabling designers to create sleek, compact, and innovative products.

Moreover, flex circuits exhibit excellent vibration resistance, reducing the risk of internal component damage caused by external forces. This characteristic makes them highly suitable for automotive and aerospace industries, where durability and reliability are of utmost importance. The flexibility and reliability of flex PCBs also simplify the assembly process, reducing manufacturing costs and enhancing time-to-market.

Materials and Manufacturing Process

The materials used in flexible PCBs play a crucial role in achieving optimal performance. Polyimide, also known as Kapton, is a popular choice for the base material due to its excellent mechanical and thermal properties. Conductive traces are typically made from copper, although other materials like silver or gold can be used depending on specific design and application requirements.

The manufacturing process of flex circuits involves several steps. It begins with patterning the conductive traces and vias on the base material using various techniques such as etching or additive manufacturing. The next step involves laminating and bonding multiple layers of flex circuits with insulating adhesive materials, creating a flexible and robust structure. Component mounting, soldering, and testing follow, ensuring the functionality and reliability of the final product.

Applications and Future Trends

The applications of flexible PCBs are vast and ever-expanding. They are widely used in consumer electronics such as smartphones, wearables, and tablets, allowing for slim designs and enhanced user experiences. The medical field benefits from flex PCBs in applications like implantable devices and medical wearables, offering comfort, flexibility, and increased functionality.

As the demand for lightweight and compact electronic solutions continues to grow, the future of flexible PCBs looks promising. Advancements in materials, such as flexible hybrid substrates, and manufacturing techniques, such as roll-to-roll processing, are opening doors to even more innovative possibilities. The integration of flexible PCBs with emerging technologies like Internet of Things (IoT) and artificial intelligence will further revolutionize the electronics industry.

Conclusion

In conclusion, implementing flexible PCBs for lightweight solutions has revolutionized the electronics industry. The advantages they offer in terms of weight reduction, flexibility, durability, and customization make them an indispensable technology in various domains. With ongoing advancements and increasing demand, flexible PCBs are set to shape the future of electronics, empowering designers to create lighter, sleeker, and more sophisticated products.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now