Eco-Friendly Electronics: Exploring Sustainable Practices with Flexible PCBs

Eco-friendly electronics have gained significant attention in recent years as society becomes increasingly aware of the need for sustainable practices in all areas of life. One crucial aspect of developing environmentally friendly electronic devices is the use of flexible printed circuit boards (PCBs). In this article, we will explore the concept of eco-friendly electronics and delve into the sustainable practices enabled by flexible PCBs.

The Rise of Eco-Friendly Electronics

With the growing concern over environmental issues, the electronics industry has been forced to reevaluate its practices and adopt more sustainable approaches. Eco-friendly electronics refer to electronic devices designed and manufactured with a focus on minimizing their impact on the environment throughout their entire lifecycle.

The Importance of Sustainable Practices

Sustainable practices in electronics manufacturing are crucial for several reasons. First and foremost, they help reduce electronic waste, which is a significant contributor to global pollution. By using materials and components that are less harmful to the environment, such as lead-free solder and recyclable packaging, the lifecycle impact of electronic devices can be significantly reduced. Furthermore, sustainable practices address the issue of resource depletion. By adopting practices that promote energy efficiency, responsible sourcing of raw materials, and recycling, manufacturers can contribute to conserving natural resources for future generations.

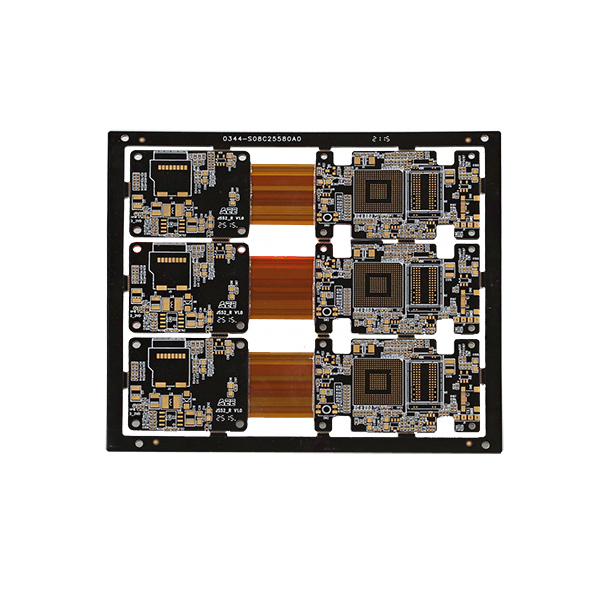

The Role of Flexible PCBs

Flexible PCBs have emerged as a key enabler of eco-friendly electronics. Unlike traditional rigid PCBs, flexible PCBs offer several advantages from a sustainability standpoint.

1. Space Efficiency: Flexible PCBs can be designed to fit into smaller and more compact devices, allowing for the optimization of space within electronic products. This feature helps reduce material consumption and, ultimately, waste generation.

2. Energy Efficiency: The flexibility of PCBs enables the creation of devices with reduced power consumption. This energy efficiency not only benefits the end-users by extending battery life but also reduces the overall demand for energy production, resulting in a smaller carbon footprint.

3. Design for Recycling: Flexible PCBs can be easily dismantled and separated from other components, making them more suitable for recycling compared to rigid counterparts. This ease of recycling facilitates the recovery of valuable materials, reducing the need for resource extraction.

Other Sustainable Practices

While flexible PCBs play a crucial role in creating eco-friendly electronics, sustainable practices extend beyond the choice of PCB materials. Here are a few additional practices adopted by manufacturers to minimize environmental impact:

1. Green Packaging: Using environmentally friendly packaging materials, such as recycled paper or biodegradable plastics, reduces the carbon footprint associated with electronic devices.

2. Energy-Efficient Production Facilities: Manufacturers can invest in energy-efficient machinery and infrastructure to minimize energy consumption during the production process.

3. Responsible E-Waste Management: Implementing proper recycling programs and promoting responsible disposal of electronic waste helps prevent hazardous materials from ending up in landfills.

The Future of Eco-Friendly Electronics

As technology continues to evolve, the push for eco-friendly electronics will only intensify. Manufacturers and consumers alike are recognizing the importance of sustainability in the electronics industry. The development of innovative materials and manufacturing techniques, along with the adoption of flexible PCBs, will drive the growth of eco-friendly electronics in the future. In conclusion, eco-friendly electronics are becoming increasingly vital in our quest for a sustainable future. The use of flexible PCBs and the adoption of sustainable practices throughout the electronics manufacturing process contribute to minimizing environmental impact and resource depletion. By embracing these practices, we can create a more sustainable and responsible electronic ecosystem for generations to come.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now