The Benefits of Using Flexible PCBs in IoT Devices

Understanding the Importance of Flexible PCBs in IoT Devices

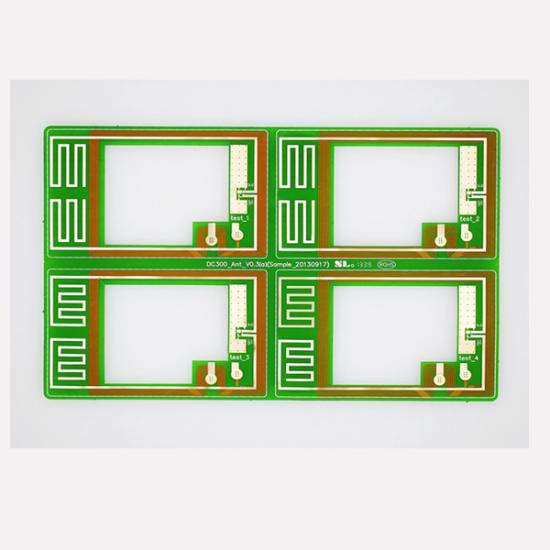

The internet of things (IoT) is revolutionizing how we interact with technology, and flexible printed circuit boards (flexible PCBs) are playing a pivotal role in this revolution. These lightweight, bendable PCBs are finding their way into an array of IoT devices, offering unique benefits that traditional rigid PCBs cannot match.

1. Enhanced Conformability for Curved Surfaces

Flexible PCBs offer unparalleled conformability, allowing them to adapt to complex curved surfaces. This is particularly beneficial in IoT devices that require curved or flexible designs, such as wearables, implantables, and flexible displays.

2. Lightweight and Compact

Flexible PCBs are lightweight and compact, making them ideal for IoT devices that require minimal weight and small form factors. This is particularly important in mobile and wearable devices where portability and convenience are essential.

3. Improved Mechanical Durability

Flexible PCBs exhibit excellent mechanical durability, surviving repeated bending and flexing without damage. This makes them well-suited for use in devices that undergo frequent movement or flexure, such as smart clothing and robotic applications.

4. Enhanced Electrical Performance

Flexible PCBs offer superior electrical performance compared to traditional rigid PCBs. They provide more reliable connections and signal transmission, even when bent or flexed.

5. Reduced Assembly Costs

Flexible PCBs simplify the assembly process, reducing the overall cost of manufacturing IoT devices. Their lightweight and compact design make them easy to handle and integrate into complex assemblies.

In conclusion, flexible PCBs play a crucial role in the development of IoT devices. Their unique properties, including conformability, lightweightness, compactness, mechanical durability, and electrical performance, make them an indispensable component in the IoT revolution. As the demand for IoT devices continues to grow, so too will the importance of flexible PCBs in enabling a range of innovative applications.