Decoding the Building Blocks: Materials in the Construction of Rigid PCBs

In the intricate world of electronics, the unsung heroes behind the seamless functioning of devices often go unnoticed. Among these silent contributors are Printed Circuit Boards (PCBs), specifically Rigid PCBs, which serve as the backbone of electronic circuitry. A crucial aspect of their design lies in the selection of materials, a process carefully orchestrated by PCBA manufacturers, Rigid Flex PCB manufacturers, and OEM PCB specialists. This article unveils the materials commonly used in the construction of Rigid PCBs, shedding light on the craftsmanship that underpins our interconnected world.

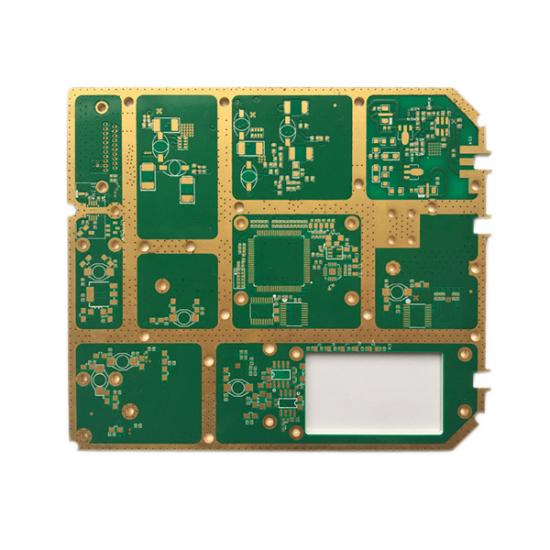

At the heart of every Rigid PCB lies the substrate, the foundational material upon which the entire circuit is built. PCBA manufacturers meticulously choose materials with the right balance of electrical and mechanical properties. Among the most prevalent choices is FR-4, a type of fiberglass reinforced with epoxy resin. FR-4 offers excellent insulation properties, dimensional stability, and durability, making it a preferred substrate for Rigid PCBs.

Conductive Traces:

For the conductive pathways that intricately weave across the PCB, copper takes center stage. Copper is favored for its exceptional electrical conductivity, corrosion resistance, and malleability. During the manufacturing process, Rigid PCB specialists carefully deposit thin layers of copper onto the substrate, forming the conductive traces that facilitate the flow of electrical signals.

Insulating Layer:

To safeguard the conductive traces and prevent unintended electrical connections, a layer of solder mask is applied. This insulating layer is typically composed of epoxy-based materials, providing protection against environmental factors, chemical exposure, and mechanical stress. The solder mask not only ensures the longevity of the PCB but also aids in component placement during assembly.

Silkscreen Printing:

The silkscreen layer adds the finishing touches to the Rigid PCB, serving both functional and aesthetic purposes. Information such as component labels, reference designators, and polarity markings are printed onto the board's surface. This layer is crucial for assembly and troubleshooting processes, providing a visual guide for technicians and engineers.

Collaboration in Crafting Excellence: PCBA, Rigid Flex PCB, and OEM PCB Manufacturers

The intricate dance of materials in Rigid PCB construction requires the expertise of manufacturers specializing in various aspects of the process. PCBA manufacturers, responsible for assembling components onto the finished PCB, collaborate closely with Rigid PCB manufacturers to ensure compatibility and reliability. Rigid Flex PCB manufacturers, dealing with boards that combine both rigid and flexible elements, bring additional expertise to the table. OEM PCB specialists, catering to original equipment manufacturers, play a pivotal role in tailoring Rigid PCB designs to meet specific device requirements.

Innovation and Adaptability: The Future of Rigid PCB Materials

As technology evolves, so do the materials used in Rigid PCB construction. Innovations in substrate materials, such as high-frequency laminates and eco-friendly alternatives, are on the horizon. These advancements aim to enhance performance, address environmental concerns, and push the boundaries of what Rigid PCBs can achieve in terms of speed, efficiency, and sustainability.

Conclusion: Beyond the Circuit, the Craftsmanship Unveiled

In the seemingly unassuming layers of a Rigid PCB, a symphony of materials harmoniously comes together, orchestrated by the skilled hands of manufacturers. PCBA specialists, Rigid Flex PCB manufacturers, and OEM PCB experts contribute their unique insights to create the sturdy foundation upon which our electronic devices thrive. As we look toward a future filled with ever-smarter and more interconnected technologies, the role of Rigid PCBs and the materials shaping their construction remains at the forefront of innovation.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now