Unveiling the Power of Rigid PCBs

In the dynamic world of electronic engineering, where innovation is constant, the role of Printed Circuit Boards (PCBs) is pivotal. Among the diverse types of PCBs, rigid PCBs emerge as the stalwart backbone, providing a robust foundation for the seamless functioning of electronic devices. This article delves into the fascinating realm of rigid PCBs, exploring their significance, applications, and how they drive the evolution of electronic technology.

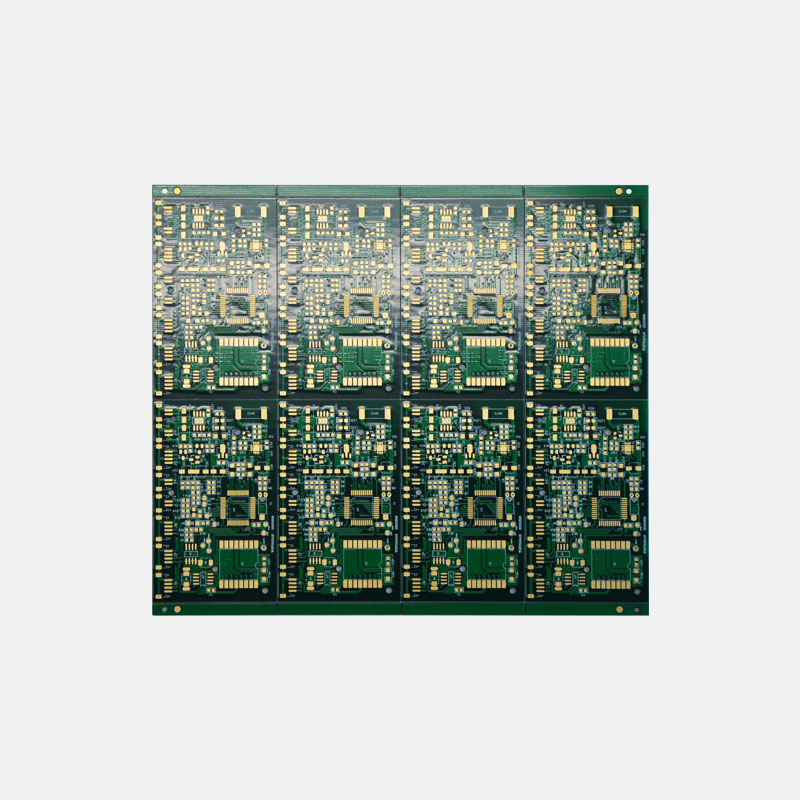

Understanding Rigid PCBs: A Foundation of Stability

Rigid PCBs, as the name suggests, are inflexible and provide a stable platform for electronic components. Comprising a solid substrate material, typically fiberglass, rigid PCBs offer a reliable structure for mounting various electronic elements, such as integrated circuits, resistors, capacitors, and connectors.

The Anatomy of a Rigid PCB: Layers and Construction

Rigid PCBs are constructed with multiple layers of materials laminated together. The typical structure includes a substrate layer (often fiberglass), a copper layer for electrical conductivity, solder mask for insulation and protection, and a silkscreen layer for component labeling. The meticulous arrangement of these layers forms the foundation for the intricate circuitry that defines electronic devices.

Versatility in Applications: Where Rigid PCBs Excel

The versatility of rigid PCBs is evident in their wide array of applications across industries. From consumer electronics like smartphones and laptops to industrial machinery, medical equipment, and automotive systems, rigid PCBs play a crucial role in ensuring the reliable performance of countless electronic devices. Their durability and stability make them ideal for applications where constant vibrations, temperature fluctuations, and environmental factors come into play.

Advantages of Rigid PCBs: Stability, Reliability, and Precision

1.Mechanical Stability: Rigid PCBs provide mechanical stability, making them suitable for applications where the board may experience physical stress or vibrations.

2.High Component Density: The rigid nature of these boards allows for a high density of electronic components, enabling the creation of complex and sophisticated circuit designs.

3.Reliability: Rigid PCBs offer reliability in terms of electrical connections. The fixed nature of the board ensures consistent performance over time.

4.Precision Manufacturing: The manufacturing process for rigid PCBs involves precision techniques, ensuring that intricate circuit designs are faithfully reproduced on the board.

Innovation in Design: Pushing the Boundaries with Rigid PCBs

As technology continues to advance, the demand for smaller, more powerful, and efficient electronic devices grows. Rigid PCBs have adapted to these demands by evolving in design and incorporating cutting-edge technologies. Advancements such as multi-layer boards, high-frequency materials, and advanced manufacturing techniques contribute to the continual evolution of rigid PCBs.

In the grand tapestry of electronic innovation, rigid PCBs stand as the unseen architects, providing the stable foundation upon which the intricate designs of electronic devices come to life. Their adaptability, reliability, and precision manufacturing make them indispensable in the ever-expanding landscape of technological progress. As we look towards a future filled with smarter and more sophisticated electronic solutions, the role of rigid PCBs as the backbone of innovation is destined to remain paramount.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now