What are the factors that affect PCB cost?

The cost of Printed Circuit Boards (PCBs) is influenced by several factors that contribute to their production and functionality. This article explores the different aspects that impact PCB cost, allowing a deeper understanding of the pricing structure behind these essential electronic components.

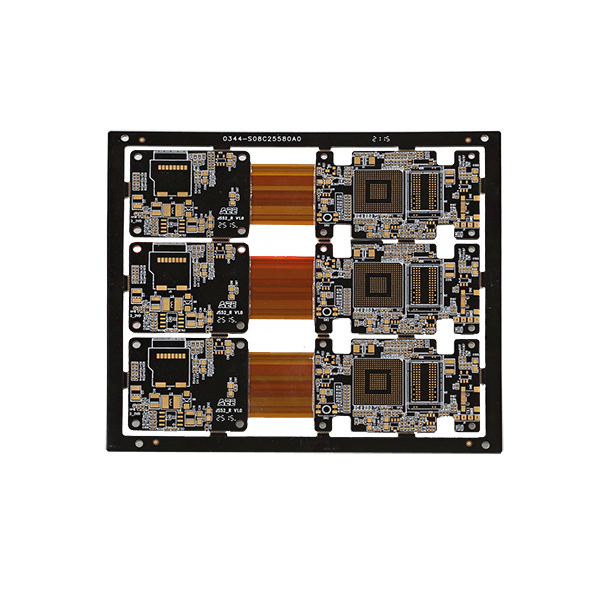

1. Complexity and Design

The complexity of a PCB design plays a pivotal role in determining its cost. Intricate designs with multiple layers, fine traces, and closely spaced components require advanced manufacturing techniques, which can significantly increase the cost. The use of advanced features like blind vias, buried vias, and controlled impedance also contribute to the complexity and cost of PCB production.

2. Material Selection

The choice of materials for PCB fabrication greatly affects the overall cost. High-quality materials, such as FR-4 fiberglass, offer better performance and durability but come at a higher price. Additionally, specialized materials like flexible PCB substrates and high-frequency laminates further increase the cost due to their unique properties. Balancing the performance requirements with cost is crucial in material selection.

3. Board Size and Thickness

The size and thickness of a PCB directly impact its cost. Larger boards require more raw materials, increased processing time, and additional manufacturing steps, resulting in higher costs. Similarly, thicker PCBs involve more intricate fabrication processes, such as longer plating cycles and lamination steps, which add to the overall cost. Optimizing the design to minimize board size and thickness can help in reducing costs.

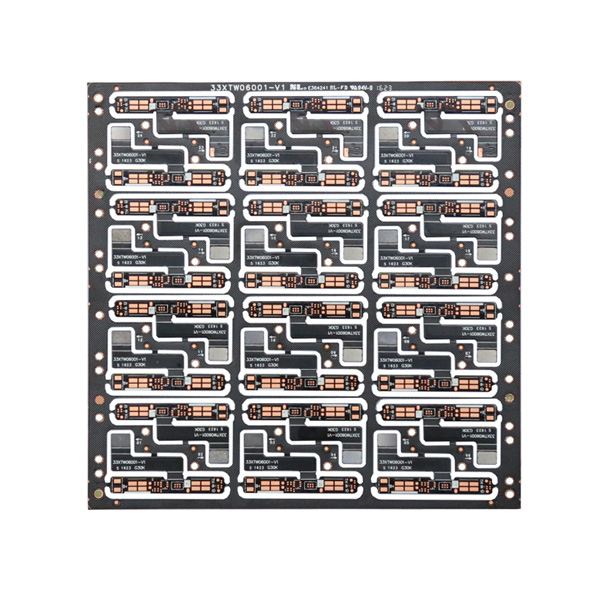

4. Component Density

The density of components on a PCB affects its manufacturing complexity and cost. A higher component density necessitates advanced assembly techniques like surface mount technology (SMT), which involves precision placement equipment and skilled labor. The increased component count also raises the material cost and requires more testing, inspection, and soldering, ultimately impacting PCB cost.

5. Volume and Manufacturing Quantity

The quantity of PCBs ordered has a significant influence on the cost per unit. PCB manufacturers offer volume-based discounts, making larger production runs more cost-effective. Prototyping and small-scale production often incur additional expenses due to setup costs, engineering support, and low economies of scale. Therefore, planning for volume manufacturing can help reduce overall PCB cost.

6. Surface Finish and Specialized Requirements

The choice of surface finish impacts the final cost of PCBs. Surface finishes like lead-free HASL, ENIG, and OSP have varying prices and performance characteristics. Additionally, specialized requirements such as gold fingers, edge plating, and impedance control add to the overall cost. Balancing the need for specialized finishes and requirements with budget constraints is crucial in managing PCB costs.

Conclusion

Understanding the factors that influence PCB cost is essential for designing and manufacturing electronic products within budget. The complexity and design intricacy, material selection, board size and thickness, component density, manufacturing quantity, and surface finishes are all variables that need careful consideration to optimize the cost without compromising quality and performance. By evaluating these factors, manufacturers and designers can strike a balance between functionality and cost-effectiveness, ultimately benefiting both the customers and the industry as a whole.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!