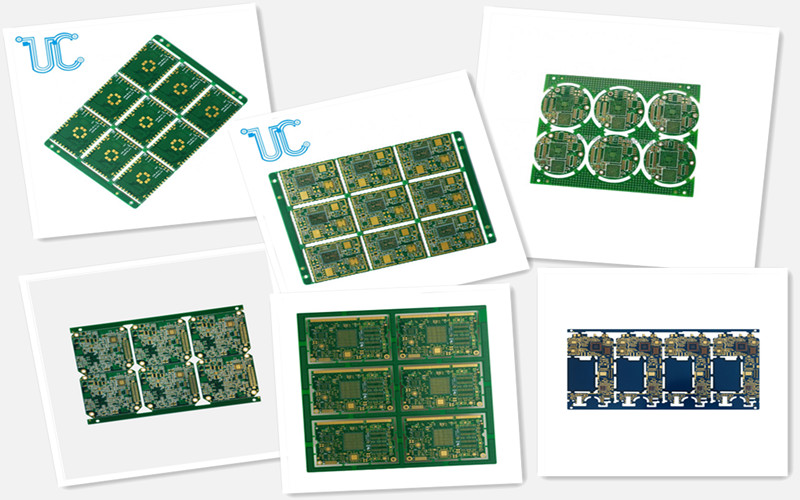

BGA PCBs / High-Density Circuitry

BGA stands for "Ball Grid Array," and PCB stands for "Printed Circuit Board." A BGA PCB is a type of circuit board that uses ball grid array technology for the attachment of integrated circuits (ICs) and other components.

In a BGA PCB, the ICs are mounted on the surface of the board, and the electrical connections are made by tiny balls of solder that are attached to the bottom of the ICs. These balls are then placed onto a grid of pads on the surface of the PCB, and the solder is melted to create a strong, permanent connection.

In recent years, the demand for electronic devices that are smaller, faster, and more powerful has grown exponentially. As a result, the use of ball grid array (BGA) technology for printed circuit boards (PCBs) has become increasingly popular. BGA PCBs are a type of circuit board that allows for the attachment of integrated circuits (ICs) and other components in a highly compact and efficient manner.

BGA technology is a significant advancement over traditional through-hole and surface-mount component technologies. BGA PCBs feature tiny balls of solder that are attached to the bottom of the ICs, which are then placed onto a grid of pads on the surface of the PCB. The solder is melted to create a strong, permanent connection that is capable of handling high-speed data transfer and other demanding applications.

One of the biggest advantages of BGA PCBs is their high-density circuitry. BGA technology allows for more efficient use of board space, which is essential for smaller devices such as mobile phones, laptops, and wearables. In addition, BGA PCBs can handle higher power levels and offer improved heat dissipation compared to traditional PCBs. This makes them ideal for high-performance applications that require fast data transfer rates and minimal heat buildup.

Another advantage of BGA PCBs is their reliability. BGA connections are less likely to fail due to their high-quality solder joints, which can withstand temperature changes and vibrations without breaking. This makes BGA PCBs ideal for applications that require high durability, such as aerospace and military applications.

However, BGA PCBs do have some challenges. One of the biggest challenges is their complexity. BGA technology requires specialized equipment and skilled operators to ensure proper alignment of the ICs with the pads on the PCB. In addition, BGA connections are not easily repairable, which can make maintenance and repair more difficult and expensive.

In conclusion, BGA PCBs are the future of high-density circuitry. They offer numerous advantages over traditional PCB technologies, including improved performance, reliability, and durability. While they do have some challenges, the benefits of BGA technology make it an attractive choice for many high-performance applications. As electronic devices continue to become smaller, faster, and more powerful, BGA PCBs will play an increasingly important role in the development of the next generation of electronics.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now