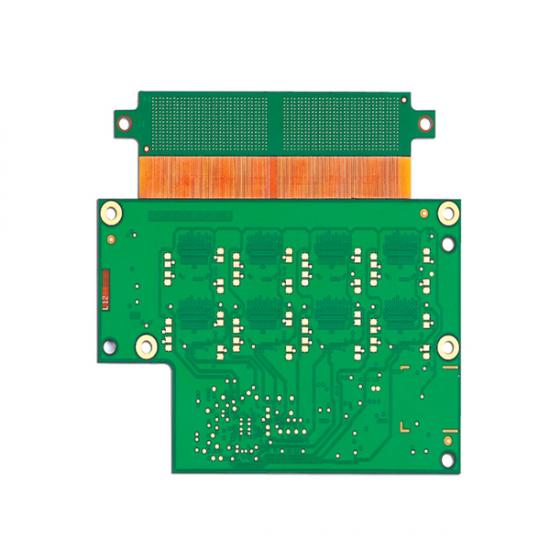

Cost-Efficient 4 Layer Rigid-Flex PCBs: Manufacturer’s Insights

When it comes to modern electronics, 4 layer rigid-flex PCBs (Printed Circuit Boards) are playing a crucial role in enhancing device performance, miniaturization, and flexibility. As a leading 4 layer rigid-flex PCBs manufacturer, Ucreate understands the growing demand for cost-effective solutions that don’t compromise on quality. In this article, we will explore the key benefits of cost-efficient 4 layer rigid-flex PCBs, the manufacturing process, and why choosing the right supplier can help optimize both performance and costs.

What Are 4 Layer Rigid-Flex PCBs?

Before diving into the specifics of cost efficiency, it's essential to understand what 4 layer rigid-flex PCBs are. These circuit boards combine the advantages of both rigid and flexible PCB technologies. Typically, 4 layer rigid-flex PCBs consist of two rigid layers and two flexible layers, allowing for complex designs that are durable yet adaptable. They are commonly used in industries like telecommunications, automotive, medical devices, and wearable technology due to their robustness and ability to save space.

Why Choose 4 Layer Rigid-Flex PCBs for Your Projects?

1.Enhanced Durability and Reliability: One of the key benefits of 4 layer rigid-flex PCBs is their high durability and resistance to stress, which makes them ideal for high-performance applications. Their rigid portions provide structural integrity, while the flexible layers allow for flexibility in designs.

2.Space-Saving Design: Rigid-flex PCBs allow for more compact designs by integrating rigid and flexible portions into one unit. This space-saving advantage is particularly important in industries like wearables or automotive devices, where size constraints are critical.

3.Reduced Assembly Costs: Instead of combining separate rigid and flexible PCBs in a device, manufacturers can design a single 4 layer rigid-flex PCB, reducing the need for additional connectors, reducing assembly time, and lowering overall costs.

4.Improved Signal Integrity: The integrated nature of a 4 layer rigid-flex PCB improves signal transmission by reducing the number of connections and the overall size of the circuit. This results in more reliable performance, which is crucial for sensitive applications such as medical or communication devices.

How Ucreate Ensures Cost-Efficiency in 4 Layer Rigid-Flex PCBs

At Ucreate, we specialize in providing cost-efficient 4 layer rigid-flex PCBs without compromising on quality. Here’s how we ensure that our customers receive the best value for their investment:

1.Streamlined Manufacturing Process: By optimizing our manufacturing process, we can reduce waste and ensure high yields, which directly translates into lower costs. Our state-of-the-art equipment allows us to produce high-quality 4 layer rigid-flex PCBs at a competitive price.

2.Material Selection: We use high-quality, cost-effective materials for the rigid and flexible layers of our 4 layer rigid-flex PCBs. Our team works with trusted suppliers to ensure that we use the best materials available at the best prices, ensuring both reliability and affordability.

3.Custom Design Solutions: At Ucreate, we understand that each project is unique. Our engineers work closely with clients to create custom designs that meet their specific requirements. This personalized approach not only ensures that the final product is cost-effective but also optimizes performance.

4.Bulk Manufacturing Discounts: For clients requiring large quantities of 4 layer rigid-flex PCBs, we offer bulk manufacturing discounts. This can significantly lower per-unit costs, helping businesses reduce overall expenses without compromising on quality.

Common Applications of 4 Layer Rigid-Flex PCBs

1.Wearable Devices: Wearables like fitness trackers, smartwatches, and medical devices benefit greatly from 4 layer rigid-flex PCBs due to their compact size and durability. These boards can handle complex circuits in a small footprint while providing flexibility for design.

2.Consumer Electronics: 4 layer rigid-flex PCBs are commonly found in high-end consumer electronics such as smartphones and tablets. Their ability to integrate rigid and flexible components into a single unit allows for sleek, space-efficient designs.

3.Automotive Applications: In the automotive industry, 4 layer rigid-flex PCBs are used for components like GPS systems, sensors, and infotainment systems, offering both high performance and durability in a compact package.

4.Medical Devices: The medical industry often requires precision and reliability, making 4 layer rigid-flex PCBs ideal for diagnostic equipment, hearing aids, and other medical devices where space and performance are paramount.

Conclusion: Why Ucreate is the Right Manufacturer for Cost-Efficient 4 Layer Rigid-Flex PCBs

Choosing the right 4 layer rigid-flex PCBs manufacturer is crucial for ensuring both quality and cost efficiency. At Ucreate, we pride ourselves on offering the best of both worlds—high-performance 4 layer rigid-flex PCBs at an affordable price. Our expertise, advanced manufacturing process, and focus on custom solutions make us a top choice for businesses in industries ranging from consumer electronics to medical devices.

By partnering with Ucreate, you can rest assured that you are getting a reliable, durable, and cost-effective product that meets your specific needs. Contact us today to learn more about our 4 layer rigid-flex PCBs and how we can help optimize your next project.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now