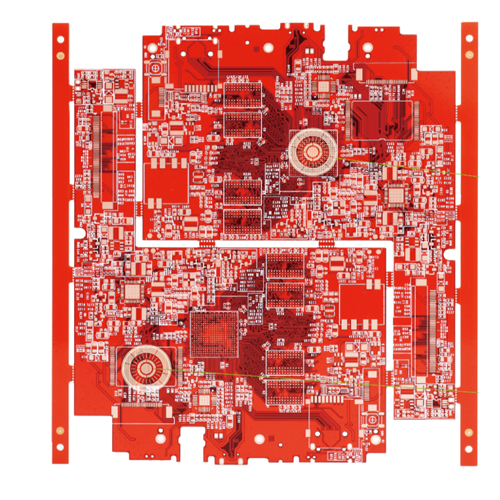

What Materials Are Used in the Construction of a Red 6-Layer FR-4 PCB?

A red 6-layer FR-4 PCB is a multilayer circuit board made with advanced materials to provide superior performance for various applications. The choice of materials directly impacts the board's durability, conductivity, and overall efficiency. Below, we explore the essential components used in the construction of these PCBs.

Core Material: FR-4

The foundation of any red 6-layer FR-4 PCB is its FR-4 material, a fiberglass-reinforced epoxy laminate. This material is widely chosen for its excellent electrical insulation, mechanical strength, and heat resistance. The "FR" in FR-4 stands for flame retardant, ensuring safety in high-temperature environments.

Copper Foil Layers

Copper foil is laminated on both sides of the FR-4 core to form the conductive layers. In a 6-layer PCB, there are multiple copper layers sandwiched between the dielectric materials. Copper provides the paths for electrical signals, with different thicknesses (measured in ounces) chosen depending on the current-carrying requirements.

Dielectric Layers

Between the copper layers, dielectric materials are used to provide insulation and maintain the board's structural integrity. These layers are often made from the same FR-4 material or specialized prepregs, which are pre-impregnated composites. They ensure reliable signal transmission and prevent crosstalk between layers.

Solder Mask

The red color of a red 6-layer FR-4 PCB comes from the solder mask, a protective coating applied to the board's surface. This layer prevents solder bridging during component assembly and adds a visually distinctive appearance. Red solder masks are often chosen for branding purposes or to improve visibility during inspections.

Silkscreen

The silkscreen layer is used to print labels, component identifiers, and alignment markings on the PCB. While not a functional material, it enhances usability during assembly and maintenance.

Adhesives and Resins

Specialized adhesives and epoxy resins are used to bond the layers of the PCB together. These materials must withstand the high temperatures of the lamination and soldering processes without degrading.

Surface Finish

The surface finish of a red 6-layer FR-4 PCB protects the exposed copper pads and ensures reliable soldering. Common finishes include:

HASL (Hot Air Solder Leveling): Cost-effective and widely used.

ENIG (Electroless Nickel Immersion Gold): Offers excellent surface flatness and durability, making it suitable for high-performance applications.

Applications of Red 6-Layer FR-4 PCBs

The materials used in a red 6-layer FR-4 PCB make it ideal for applications requiring high reliability and precision, including:

Telecommunication Equipment: For signal integrity in routers and switches.

Industrial Automation: Ensures durability in harsh environments.

Consumer Electronics: Used in compact devices with dense circuitry.

Aerospace and Defense: Reliable for mission-critical systems.

Conclusion

The construction of a red 6-layer FR-4 PCB involves carefully selected materials like FR-4, copper foil, dielectric layers, and protective coatings to ensure optimal performance. These boards are indispensable in advanced electronic applications, offering durability, efficiency, and a visually striking appearance with their red solder mask.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now