Enhancing Portability: The Role of Rigid Flex PCBs in Modern Electronic Devices

Empowering Compact and Flexible Designs for the Modern Digital Landscape

The Evolution of Printed Circuit Boards

The printed circuit board (PCB) has been a fundamental component in the electronics industry, playing a crucial role in the development of modern electronic devices. As technology has advanced, the demand for more compact, versatile, and efficient PCBs has grown exponentially. One innovative solution that has emerged to meet these evolving needs is the rigid flex PCB, a hybrid design that combines the durability of rigid boards with the flexibility of flexible circuits.

Understanding Rigid Flex PCBs

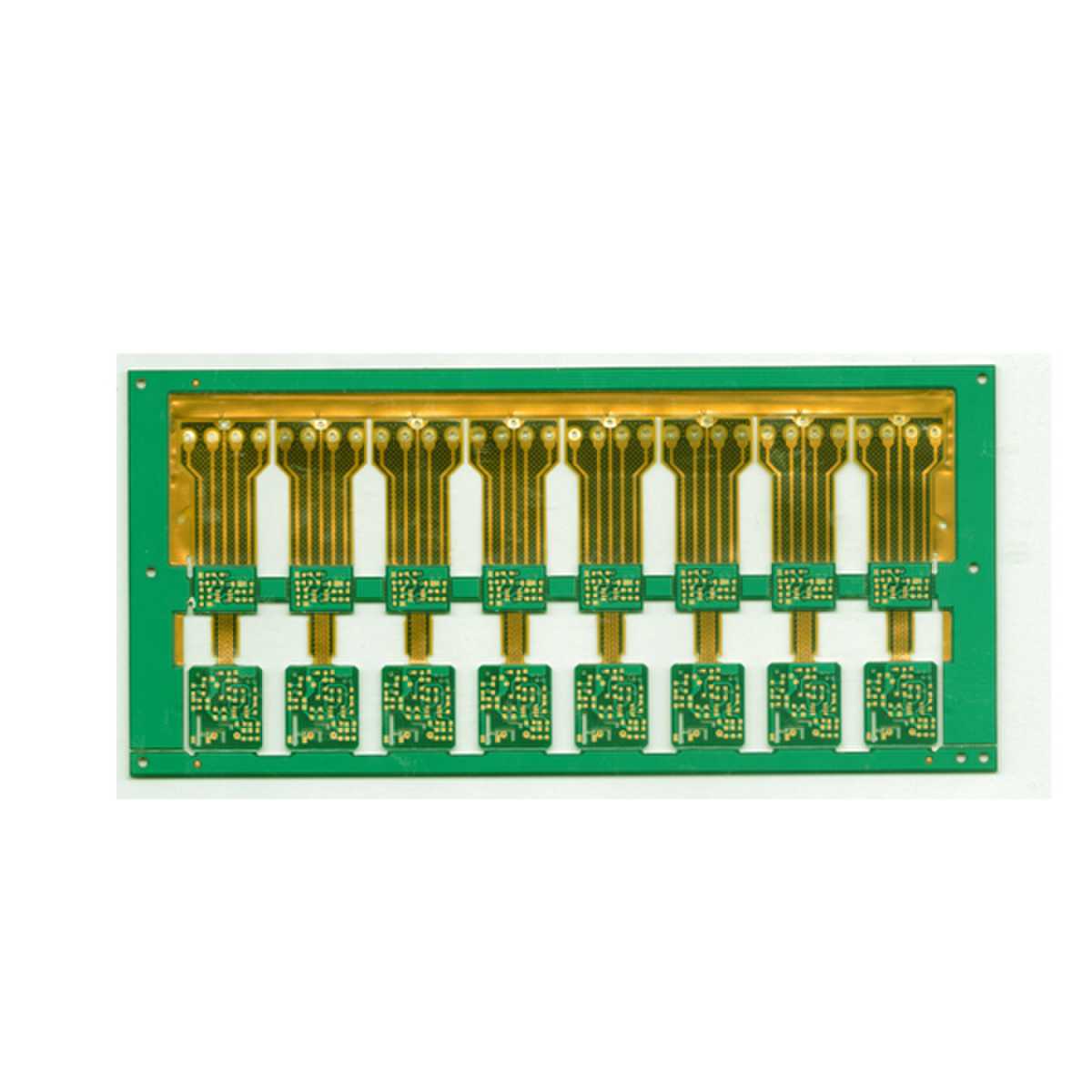

Rigid flex PCBs are a hybrid design that seamlessly integrates rigid and flexible circuit board materials, creating a single, unified structure. This unique combination allows for the creation of compact, lightweight, and highly adaptable electronic products. The rigid portions of the board provide structural integrity and support for components, while the flexible segments enable smooth bending, folding, and integration into complex, space-constrained designs.

Advantages of Rigid Flex PCBs

The integration of rigid and flexible materials in a single PCB design offers a multitude of advantages that make rigid flex PCBs an increasingly popular choice for modern electronic devices. These advantages include:

1. Enhanced Portability and Miniaturization: The flexible segments allow for the creation of more compact and portable electronic devices, as the PCB can be folded, curved, or shaped to fit into smaller enclosures.

2. Improved Reliability and Durability: The rigid portions provide structural support and protection for sensitive components, while the flexible interconnections enhance the overall resilience of the PCB, making it more resistant to stress, vibrations, and physical impacts.

3. Reduced Assembly Complexity: Rigid flex PCBs eliminate the need for separate rigid and flexible boards, simplifying the assembly process and reducing the overall component count, thereby improving manufacturing efficiency and reliability.

4. Design Flexibility: The combination of rigid and flexible materials enables designers to create more innovative and complex product configurations, allowing for the integration of multiple functionalities within a compact form factor.

Applications of Rigid Flex PCBs

Rigid flex PCBs have found widespread applications across a diverse range of industries, from consumer electronics to aerospace and medical devices. Some of the key sectors where rigid flex PCBs are transforming product design and performance include:

1. Wearable Electronics: The flexibility and compact nature of rigid flex PCBs make them ideal for integrating into wearable devices, such as smartwatches, fitness trackers, and medical monitoring equipment, where space is at a premium.

2. Portable Electronics: Smartphones, tablets, and other portable electronic devices rely on rigid flex PCBs to achieve their thin, lightweight, and durable designs, enabling enhanced portability and user experiences.

3. Aerospace and Defense: Rigid flex PCBs excel in applications where reliability, durability, and compact design are critical, such as in aerospace, military, and space exploration equipment.

4. Medical Devices: The adaptability and biocompatibility of rigid flex PCBs make them a preferred choice for medical devices, including surgical tools, implants, and diagnostic equipment, where complex geometries and flexibility are essential.

5. Industrial Automation: Rigid flex PCBs are widely used in industrial automation and control systems, where the combination of rigid and flexible components allows for seamless integration into various machinery and equipment.

The Future of Rigid Flex PCBs

As technology continues to evolve, the role of rigid flex PCBs in shaping the future of electronic devices is expected to become even more prominent. With ongoing advancements in materials, manufacturing processes, and design techniques, the capabilities of rigid flex PCBs are constantly expanding. From enabling the development of even more compact and versatile electronic products to supporting the integration of emerging technologies, such as flexible displays and 5G connectivity, rigid flex PCBs are poised to play a crucial role in the continued evolution of the digital landscape.

In conclusion, the integration of rigid and flexible circuit board materials in the form of rigid flex PCBs has revolutionized the way modern electronic devices are designed and manufactured. By offering enhanced portability, improved reliability, and increased design flexibility, rigid flex PCBs have become an essential component in a wide range of industries, empowering the creation of innovative, compact, and highly adaptable electronic products. As the demand for more versatile and compact electronic devices continues to grow, the role of rigid flex PCBs in shaping the future of the digital landscape is poised to become even more significant.