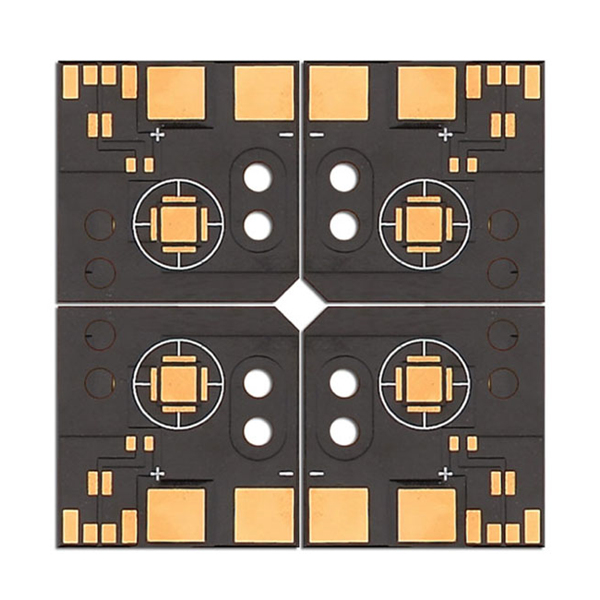

Power Up: The Advantages of Metal Core PCBs for Power Electronics

In the realm of power electronics, the choice of printed circuit boards (PCBs) is critical. Metal Core PCBs (MCPCBs) have emerged as a reliable solution, offering unique advantages that traditional PCBs often lack. Let's delve into why MCPCBs are becoming increasingly popular and the benefits they bring to power electronic systems.

Superior Heat Dissipation:

Metal Core PCBs are designed with a thermally conductive metal substrate, typically aluminum, which effectively dissipates heat generated by power components. This thermal management capability ensures optimal performance and longevity of power electronics, even under high load conditions.

Enhanced Durability:

With their metal core construction, MCPCBs exhibit greater durability compared to standard FR4 PCBs. The metal substrate provides robustness against mechanical stress, vibration, and thermal cycling, making MCPCBs ideal for demanding environments where reliability is paramount.

Improved Electrical Performance:

Metal Core PCBs offer superior electrical performance, particularly in high-frequency applications. The metal substrate reduces signal loss and electromagnetic interference (EMI), ensuring stable operation of power electronic circuits. This enhanced electrical performance translates to better efficiency and accuracy in power transmission.

Compact and Lightweight Design:

Despite their sturdy construction, MCPCBs are inherently lightweight and compact. This makes them well-suited for space-constrained applications such as LED lighting, automotive electronics, and power converters. The compact design of MCPCBs allows for efficient integration into various electronic systems without compromising performance.

Compatibility with High-Power Components:

MCPCBs are designed to accommodate high-power components such as LEDs, power transistors, and diodes. The metal core substrate provides a low-impedance path for current flow, minimizing voltage drop and ensuring optimal power delivery. This compatibility with high-power components makes MCPCBs an ideal choice for power electronics requiring robust performance.

Conclusion:

In summary, metal core pcbs offer a host of advantages for power electronics applications. From superior heat dissipation and enhanced durability to improved electrical performance and compatibility with high-power components, MCPCBs are revolutionizing the way power electronic systems are designed and implemented. As the demand for efficient and reliable power solutions continues to grow, MCPCBs are set to play a pivotal role in shaping the future of power electronics.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now