What materials are used in FR-4 PCB manufacturing?

An In-depth Look at the Components of FR-4 PCBs

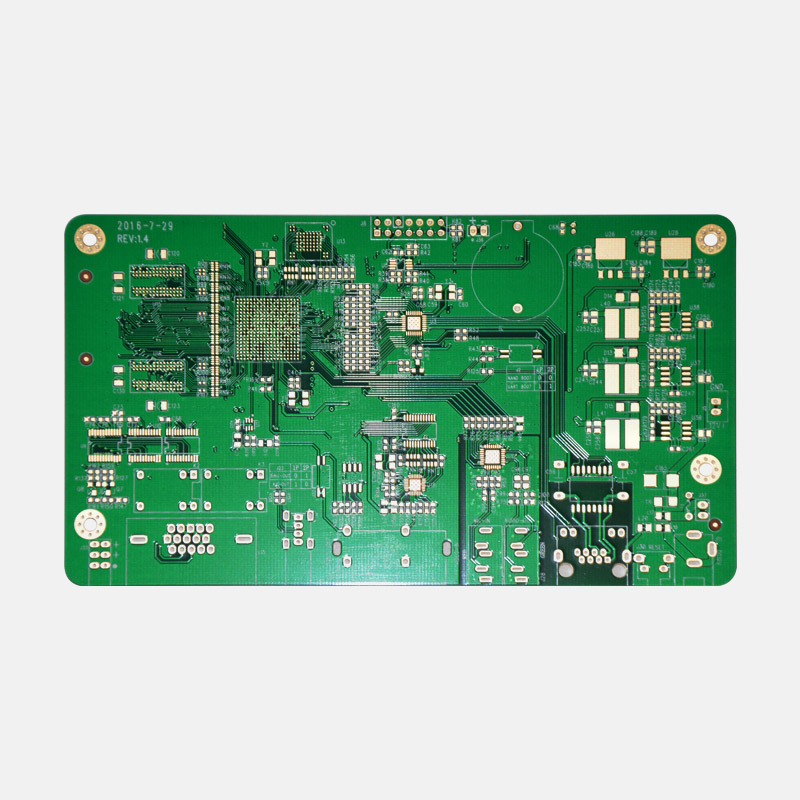

Printed Circuit Boards (PCBs) play a crucial role in the modern electronics industry. FR-4, a widely used material in PCB manufacturing, offers numerous benefits such as superior insulation, stability, and durability. To understand FR-4 PCB manufacturing thoroughly, it is important to delve into the various materials that make up these boards.

1. Substrate Material - High-Quality Epoxy Resin

The FR-4 substrate itself is composed of a high-quality epoxy resin. This resin provides excellent mechanical strength, high-temperature resistance, and electrical insulation properties. Fiberglass or woven glass fabric is combined with the epoxy resin to enhance board rigidity.

2. Reinforcement Material - Woven Glass Fabric

Woven glass fabric acts as a reinforcement material in FR-4 PCB manufacturing. This fabric is typically made from glass filaments and offers excellent dimensional stability, heat resistance, and mechanical strength. The type of glass fabric used can vary depending on the desired PCB properties.

3. Copper Foil - Vital for Conductivity

The conductive tracks on a PCB are formed using copper foil. Copper is preferred due to its high electrical conductivity. The copper foil is laminated onto the FR-4 substrate and etched to create the desired circuitry. A thin layer of copper is also applied to the drill holes to ensure electrical connectivity between layers.

4. Solder Mask - Protecting the Circuitry

A solder mask is applied over the copper traces to protect them from environmental factors and prevent unintentional solder bridging during assembly. The solder mask also provides insulation and enhances the overall aesthetics of the PCB. Typically, a green color is used, although other colors are also available.

5. Surface Finish - Ensuring Proper Solderability

The surface finish on FR-4 PCBs is crucial for ensuring proper solderability and protecting the copper traces. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservatives). Each surface finish offers different benefits, such as improved solder joint quality or extended shelf life.

Conclusion

In conclusion, FR-4 PCBs are composed of several essential materials that collectively contribute to their excellent performance. The high-quality epoxy resin substrate, woven glass fabric reinforcement, copper foil conductive tracks, solder mask, and surface finish all work together to create robust, reliable, and efficient electronic circuit boards. Understanding the materials used in FR-4 PCB manufacturing allows for informed decision-making and ensures the production of high-quality PCBs for various applications.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now