The Role of Flexible PCBs in Next-Gen Smart Devices

Understanding the Essence of Flexible PCBs in Smart Devices

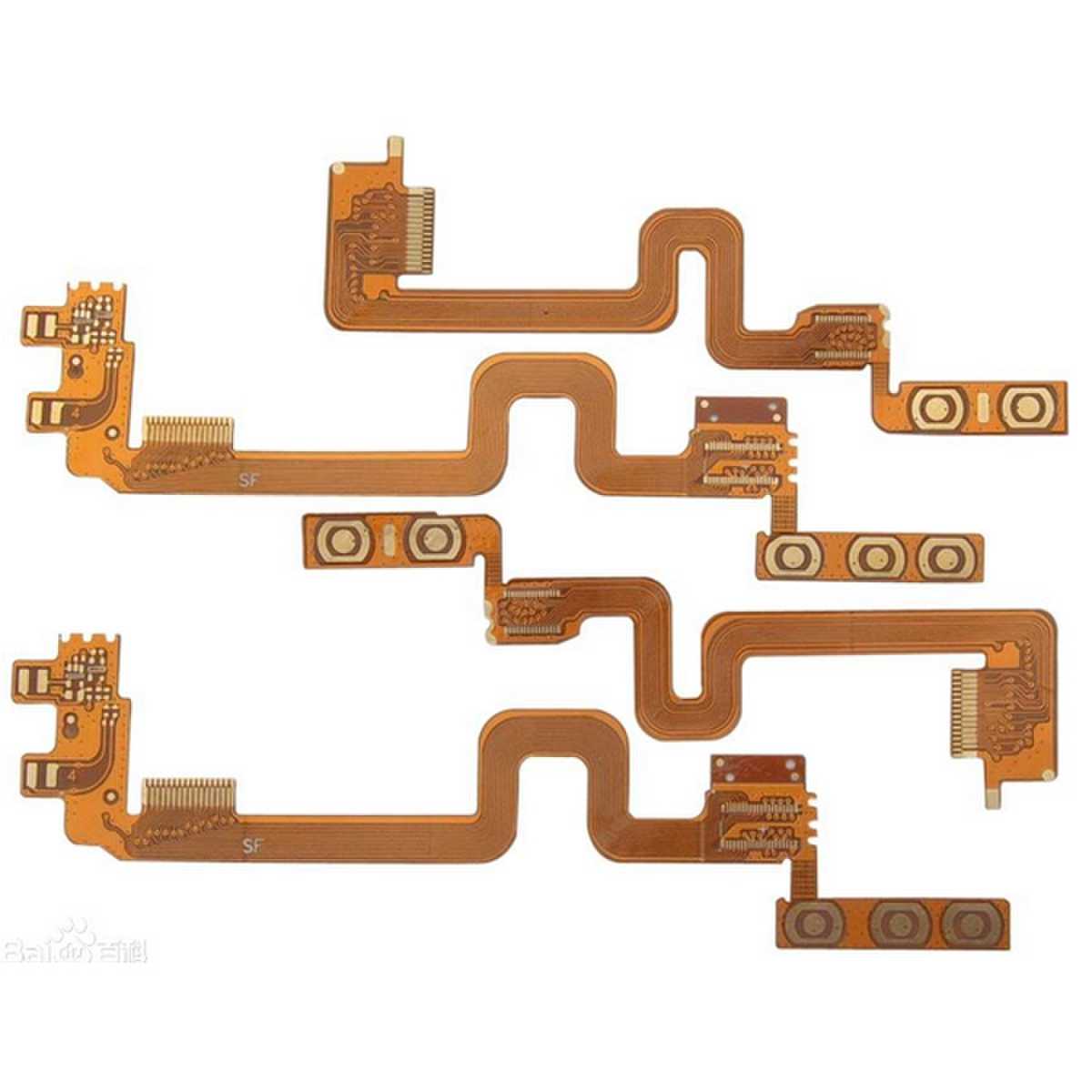

The evolution of technology has opened doors to a new era of miniaturization and portability in smart devices. With the advent of flexible printed circuit boards (flexible PCBs), the design and functionality of these devices have reached new heights. These PCBs provide unparalleled flexibility, allowing for a wide range of innovative form factors and functions.

Benefits of Flexible PCBs in Smart Devices

Flexible PCBs offer several advantages in next-generation smart devices. They provide designers with more freedom in terms of device design, allowing for a wider range of shapes and sizes. This flexibility enables the creation of devices that are more ergonomic and user-friendly, such as curved smartphones or flexible wearables.

In addition, flexible PCBs reduce the overall weight of devices, making them more portable and convenient. This is particularly beneficial in devices that are worn or carried constantly, such as smartwatches or fitness trackers.

Moreover, the durability of flexible PCBs makes them ideal for use in ruggedized devices, such as those used in extreme environments or for military applications.

Technological Advancements in Flexible PCBs

The technology behind flexible PCBs has undergone significant advancements in recent years. Advanced materials, such as polyimides and liquid crystal polymers, have been developed to improve the durability and performance of these boards.

In addition, the use of additive manufacturing techniques has enabled the production of flexible PCBs with intricate designs and minute details.

Furthermore, the integration of sensors and other components onto flexible PCBs has opened up new possibilities for smart devices.

Applications of Flexible PCBs

Flexible PCBs have found applications in a wide range of next-generation smart devices. One of the most prominent examples is in the healthcare industry, where they are used in the production of wearable devices for monitoring vital signs and other health-related data.

In the consumer electronics market, flexible PCBs can be found in smartphones, tablets, and laptops, contributing to their lightweight and sleek designs.

Moreover, in the automotive industry, these boards are used in the production of advanced driver assistance systems and other vehicle components.

Challenges and Future Prospects

Despite the numerous benefits of flexible PCBs, there are still challenges that need to be addressed. One of the main challenges is the production cost, which can be prohibitive for some applications.

In addition, there are technical challenges related to the complexity of manufacturing and assembling flexible PCBs.

However, with ongoing research and technological advancements, it is expected that these challenges will be overcome in the near future.

Flexible PCBs will continue to play a pivotal role in the design and functionality of next-generation smart devices. As the demand for smaller, more portable, and innovative devices increases, the use of flexible PCBs will become even more prevalent.