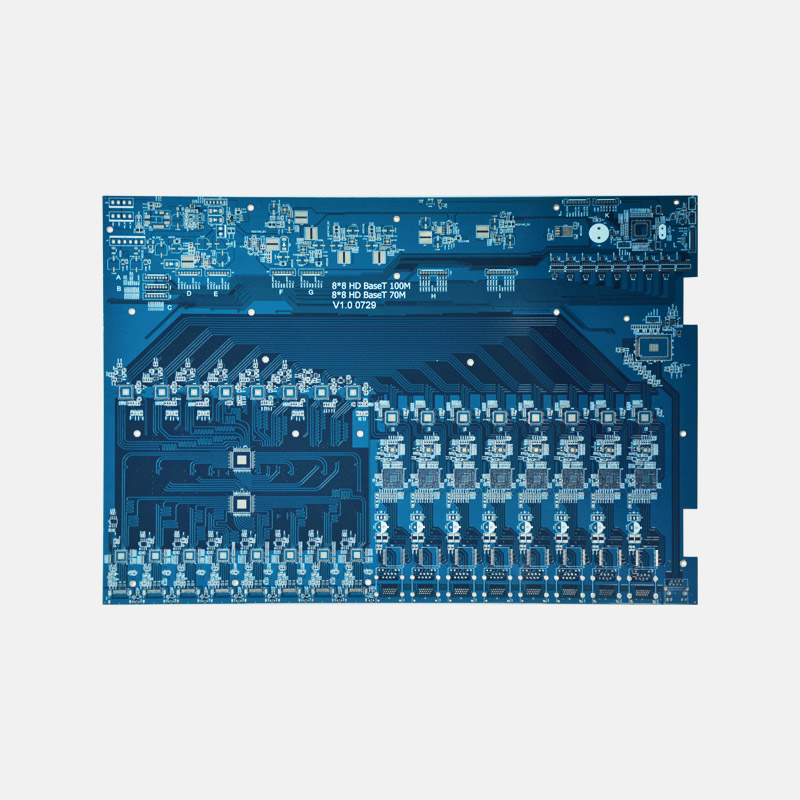

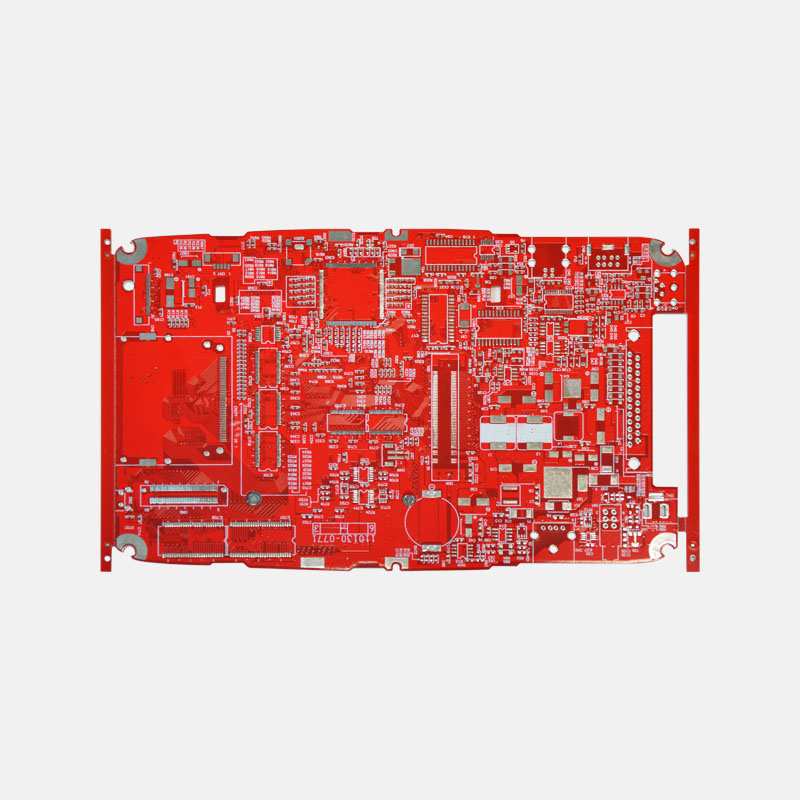

The Dominance of FR-4 in the PCB Industry

In the world of printed circuit boards (PCBs), one material has reigned supreme for decades: FR-4. This substrate material has become the standard choice for PCB manufacturing due to its exceptional properties and widespread availability. In this article, we will delve into the reasons why FR-4 has become such a popular option for PCBs, examining its key characteristics and exploring its advantages over alternatives.

1. Superior Electrical Properties

One of the major reasons why FR-4 stands out as the go-to material for PCBs is its excellent electrical properties. FR-4 boards offer high insulation resistance, low dielectric constant, and low dissipation factor, ensuring minimal signal loss and interference. They also have good thermal stability, allowing for reliable performance in a wide range of operating temperatures. These electrical properties make FR-4 the preferred option for various applications, including consumer electronics, telecommunications, and automotive sectors.

2. Mechanical Strength and Durability

Another key advantage of FR-4 lies in its exceptional mechanical strength and durability. FR-4 PCBs possess high flexural and tensile strength, making them resistant to bending, warping, and breaking. This robustness allows for reliable functioning even in demanding environments, where vibrations, shocks, and impacts may occur. Compared to alternative materials like polyimide or ceramic, FR-4 provides better structural stability, ensuring the longevity and reliability of PCBs.

3. Excellent Flame Retardancy

FR-4 also stands out for its exceptional flame retardancy, making it a safe choice for PCB applications. FR-4 boards meet stringent UL-94 standards for flame resistance, reducing the risk of fire and enhancing overall safety. With the increasing focus on product safety and regulatory compliance, the flame retardancy of FR-4 is a crucial factor that contributes to its popularity in various industries, especially those with stringent safety requirements such as aerospace and medical sectors.

4. Cost-Effectiveness and Availability

When it comes to manufacturing considerations, the cost-effectiveness and availability of FR-4 play a significant role in its popularity. FR-4 is a relatively inexpensive material, making it more accessible and economical for PCB production, especially for large-scale manufacturing. Additionally, FR-4 substrates are widely available from numerous suppliers worldwide, ensuring a steady supply and reducing production lead times. These factors make FR-4 a highly attractive option for PCB manufacturers, contributing to its dominance in the industry.

5. Compatibility with Standard Processes

FR-4's compatibility with standard PCB fabrication processes is another factor that makes it a popular choice. FR-4 materials can be easily processed using conventional manufacturing techniques such as drilling, etching, and soldering. This compatibility with standard processes simplifies PCB production and allows for efficient integration into existing manufacturing lines. Furthermore, FR-4 substrates can support multiple layer counts, facilitating the design and production of complex PCBs.

Conclusion

FR-4 material has established itself as the preferred choice for PCBs due to its superior electrical properties, mechanical strength, flame retardancy, cost-effectiveness, and compatibility with standard processes. These key advantages have made FR-4 a versatile and widely available option that caters to the diverse needs of the electronics industry. As technology continues to advance, FR-4 is expected to maintain its dominance as the go-to material for PCB manufacturing.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now