Revolutionizing Electronics: The Wonders of Flexible PCBs

In the ever-evolving landscape of electronics, innovation has become synonymous with flexibility, adaptability, and efficiency. Flexible Printed Circuit Boards (Flexible PCBs or FPCBs) have emerged as a transformative technology, offering a host of advantages over traditional rigid PCBs. This article explores the unique features and applications of Flexible PCBs, shedding light on their role in shaping the future of electronic devices.

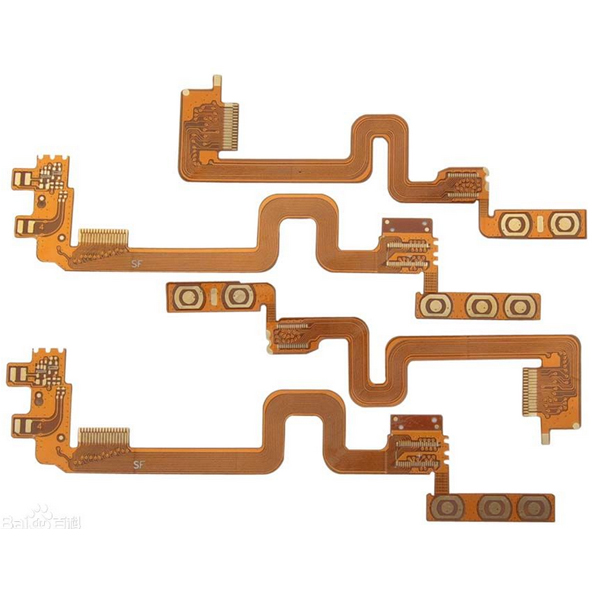

Understanding Flexible PCBs:

Flexible PCBs are a type of circuit board that, unlike rigid PCBs, can bend and flex without compromising their functionality. They are typically composed of a flexible substrate material, such as polyimide, that allows for intricate and three-dimensional designs. The flexible nature of these PCBs opens up a world of possibilities for engineers and designers seeking innovative solutions in various industries.

Key Features:

1.Bendability and Flexibility:

The most distinguishing feature of Flexible PCBs is their ability to bend and flex, making them ideal for applications where space is limited or unconventional shapes are required. This flexibility allows for the creation of compact and lightweight electronic devices.

2.Space Efficiency:

Flexible PCBs enable the design and integration of circuits in tight or irregular spaces where traditional rigid PCBs may not fit. This space efficiency is particularly valuable in industries such as wearable technology, medical devices, and aerospace, where size and weight constraints are critical.

3.Reliability and Durability:

Despite their flexibility, Flexible PCBs are designed to maintain reliability and durability. They can withstand bending, vibration, and dynamic movements, making them suitable for applications in environments where rigid boards may be prone to failure.

4.Complex Circuitry:

Flexible PCBs allow for the creation of intricate and complex circuitry. Their design versatility enables engineers to incorporate multiple layers of circuits, providing a compact solution for devices with advanced functionalities.

Applications of Flexible PCBs:

1.Wearable Technology:

The rise of wearable devices, such as smartwatches and fitness trackers, has been made possible by the integration of Flexible PCBs. These boards conform to the shape of the wearable, offering a comfortable and seamless user experience.

2.Medical Devices:

In the medical field, Flexible PCBs find applications in devices like medical implants, diagnostic equipment, and monitoring devices. Their flexibility allows for comfortable integration into the human body, facilitating advancements in healthcare technology.

3.Aerospace and Automotive:

The aerospace and automotive industries benefit from the lightweight and space-saving characteristics of Flexible PCBs. They are used in navigation systems, control panels, and various electronic components in aircraft and automobiles.

4.Consumer Electronics:

Flexible PCBs are increasingly used in smartphones, tablets, and other consumer electronics. Their ability to adapt to the shape of the device allows for creative and compact designs, contributing to the sleek aesthetics of modern gadgets.

Conclusion:

Flexible PCBs have ushered in a new era of innovation in the electronics industry. Their unique combination of bendability, space efficiency, reliability, and adaptability has opened doors to previously unimaginable designs and applications. As technology continues to advance, Flexible PCBs are poised to play a pivotal role in shaping the future of electronic devices, providing solutions that push the boundaries of what is possible in the world of electronics.

Send PCB Files to Sales@ucreatepcba.com, We Will Quote You Very Soon!

Request PCB Manufacturing & Assemble Quote Now